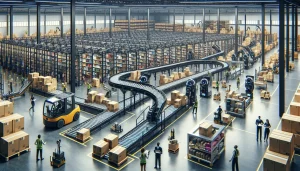

Inside the seemingly mundane walls of a fulfillment center, there’s a riveting ballet of processes at play. The coherent chaos among the humming conveyor belts, bustling forklifts, and meticulously arranged shelves is nothing short of a masterpiece. With a customer order as the conductor, this orchestra fine-tunes itself to synchronicity unheard of outside the grand production that is a fulfillment center.

Have you ever wondered how your online order journeys from the ‘buy’ button to your doorstep? Step behind the curtain as we unravel the insider’s perspective from the heart of a fulfillment center, illuminating how orders transform from fleeting digital requests into tangible packages at your door. Curious about diving into Amazon’s order fulfillment service? This post is your gateway to understanding how the magic happens, offering insight into the process from button click to doorstep delivery.

By the end of this tour, you’ll possess an insider’s grasp of fulfillment center operations, giving you an edge in any e-commerce conversation. After all, they say knowledge is power! Now let’s get this curtain raised, shall we?

Turning Green for Gain 💚

Approximately 50% of US consumers are willing to pay more for sustainable packaging, showcasing the impact of eco-friendly practices on consumer preferences.

27% higher customer satisfaction

Professional delivery features:

- Real-time GPS tracking

- Automated ETA updates

- Delivery confirmation photos

- 27% higher delivery satisfaction

Unveiling the Order Processing in Fulfillment Centers: A Step-by-Step Guide

Step 1: Receiving the Order in Fulfillment Services

The genesis of any order fulfillment service starts with the order being placed by the customer. This marks the first step, ‘Receiving the Order.’ The entire process hinges on the accuracy of the order placement, thereby making it vital to ensure a seamless workflow. Are you starting with ecommerce fulfillment services? Discover how to effectively manage the placement, processing, and dispatch of your digital store’s orders.

Once the order is placed, it is forwarded to the fulfillment center where the order information is scrutinized thoroughly. This step is crucial as it prevents any possible discrepancies or inaccuracies from creeping into the system and causing complications down the line.

As part of the order-receiving process, the order is then logged into the center’s internal system. This paves the way for the subsequent steps in the order processing operation, setting the stage for its smooth execution.

Step 2: Picking the Product

With the order successfully received and logged into the system, we now move on to the next phase: ‘Picking the Product.’ This is where the product is physically picked up from the warehouse to be prepared for shipment.

This entire step is governed by meticulous organization and efficient use of warehouse space. Every product is assigned a specific spot in the warehouse to facilitate easy identification and swift retrieval.

The significance of the picking process

The picking process holds great significance in the grand scheme of the order fulfillment process. It’s not only about getting the right product but also about speed and accuracy. Inefficiencies here could bottleneck the entire operation, leading to delays and customer dissatisfaction.

Step 3: Packaging the Product in Order Fulfillment Services

Following the successful picking of the product, it is now time for ‘Packaging the Product.’ This is the stage where human touch meets systematic precision, as each item is carefully packaged to ensure safe and secure delivery.

Packaging also includes labeling the product with crucial delivery information. Incorrect labeling could lead to misplaced or lost orders, thereby emphasizing the significance of this process.

Role of packaging material

An often overlooked but significant part of this process is the choice of packaging material. Sustainable and durable packaging materials are not just seen as a corporate responsibility, but also as a reflection of the brand’s image and values.

The Profit Power of Packaging 📈

Enhancing product packaging has led to a 30% boost in profit for businesses, illustrating the significant return on investment from packaging improvements.

Step 4: Shipping the Order

Finally, we arrive at the last step of the order fulfillment process: ‘Shipping the Order.’ With the items packed and labeled, they’re now dispatched toward their respective destinations.

The center’s responsibility doesn’t end here. They continuously track the package’s journey using advanced tracking systems until it reaches the customer’s doorstep. This assures customers of their order’s safety while in transit.

Thus, the cycle of order processing in a fulfillment center comes full circle. From receiving the order to ensuring it reaches the customer, every step significantly influences the customer’s overall experience.

This deep understanding of the process helps you appreciate the work that goes on behind the scenes in every fulfillment center. Throw into the mix the complexities of scaling these operations, it becomes evident why fulfillment companies everywhere are always looking to optimize this critical process.

The Role of Inventory Management in Fulfillment Centers

Importance of Accurate Inventory Tracking

The heartbeat of any fulfillment center is its inventory management system. It’s essential to know what you have, where it is, and how much of it is available at your own warehouse at any given moment. Inaccurate inventory tracking can lead to a plethora of issues, like wasted resources, unfulfilled orders, and eventually, unhappy customers. Therefore, updating and maintaining a constant, accurate grasp of inventory is crucial to the smooth running of a fulfillment center.

The potential complexities of accurate inventory tracking can be mitigated with the use of technology. Today, most fulfillment centers leverage software and equipment that provide real-time updates about available inventory, received items, dispatched orders, and stock movements within the warehouse. The aim is to reduce manual errors, save precious time, and enhance overall productivity. Discover methods to implement complimentary delivery options that allure patrons while maintaining your inventory accuracy and safeguarding revenue returns.

The Outsourcing Boom in E-commerce 🚚

Over 50% of businesses have outsourced their order fulfillment operations, signaling a major shift towards external fulfillment solutions to enhance efficiency and resource management.

Techniques for Efficient Inventory Management

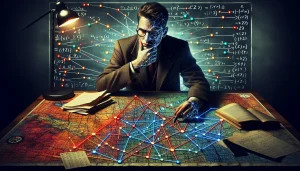

Streamlining inventory management is a two-part process: deploying the right technology and implementing efficient operational practices. Dependence only on technology is not enough. It’s also important to structure inventory layout strategically to minimize retrieval time, conduct regular audits to validate system data and adopt inventory optimization techniques like FIFO (First-In-First-Out) or JIT (Just-In-Time) to avoid overstocking and understocking scenarios.

WMS (Warehouse Management System) and IMS (Inventory Management System) are widely used for maintaining and regulating inventory in a highly systematic and process-oriented way. The systems can provide granular real-time data on stock levels, streamline the order-picking process, and reduce handling times. This allows warehouse workers to focus more on critical tasks that truly need human intervention.

ABC analysis is another relevant technique used in inventory management. This is a method of grouping inventory based on importance and value, where class A items are high-value products that require more security and high-quality storage, class B items are moderate-value products, and class C encompasses high-volume, low-value items. ABC analysis helps in managing warehouse space efficiently and ensuring high-priority products always remain stocked and accessible.

The Impact of Effective Inventory Management

Successful inventory management ensures order fulfillment is always on track. It enables real-time visibility of inventory status, enhanced productivity, reduced operational costs, and more satisfied customers. It also promotes a culture of accuracy and efficiency, which goes a long way in building a robust fulfillment center.

Seeking Accuracy in Inventory 📊

The average inventory accuracy level in US retail stands at 63%, underlining the urgent need for improvement in inventory tracking systems.

Remember, inventory management is not a one-off task. It requires constant tracking, measuring, and adjusting to ensure a fulfillment center operates smoothly. It’s the silent backbone that holds the whole operation together.

Shipping and Delivery from Fulfillment Centers: Ensuring Speed and Efficiency

The Role of Logistics in Fulfillment Centers

The unassuming field of logistics runs the world. When suitable logistics structures back fulfillment centers, magic happens. It’s logistics’ influential role that refines the various fulfillment warehouse centers’ operations distilled into a smooth, efficient machine.

Imagine a highly-tuned assembly line on steroids. Each component – the inventory, software, equipment, personnel, and shipping carriers – works harmoniously to meet customer orders on time. That’s logistics in action in a fulfillment center.

Inventory Tracking Challenges 🚨

Late shipments are the top operational concern for more than 33% of businesses, highlighting the critical role of efficient inventory management in meeting delivery commitments.

Understanding Logistics Components

To fully grasp logistics’s pivotal role, understanding its main components is critical. These delineations run into but are not restricted to – warehouse management, inventory control, order management, return & exchanges mechanism, and shipping carrier tie-ups. It’s these elements, with robust coordination, that drive a successful fulfillment center.

The precision and synchronization of logistics are what enables an order to go from a simple digital click to a packaged product awaiting delivery, without a hitch. Efficiency is the word of the day, with no room for error.

How Fulfillment Centers Ensure Fast Delivery

Think of quick delivery as the holy grail for e-commerce businesses. It shifts from a nice-to-have to an absolute must-have in today’s fiercely competitive digital marketplace. How do robust fulfillment centers achieve this?

The first piece of the puzzle comes from the staggering logistical efficiency mentioned earlier. However, quick shipping from fulfillment providers goes beyond logistics, transferring into sophisticated operational strategies such as distributed inventory.

The Strategy Behind Fast Shipping

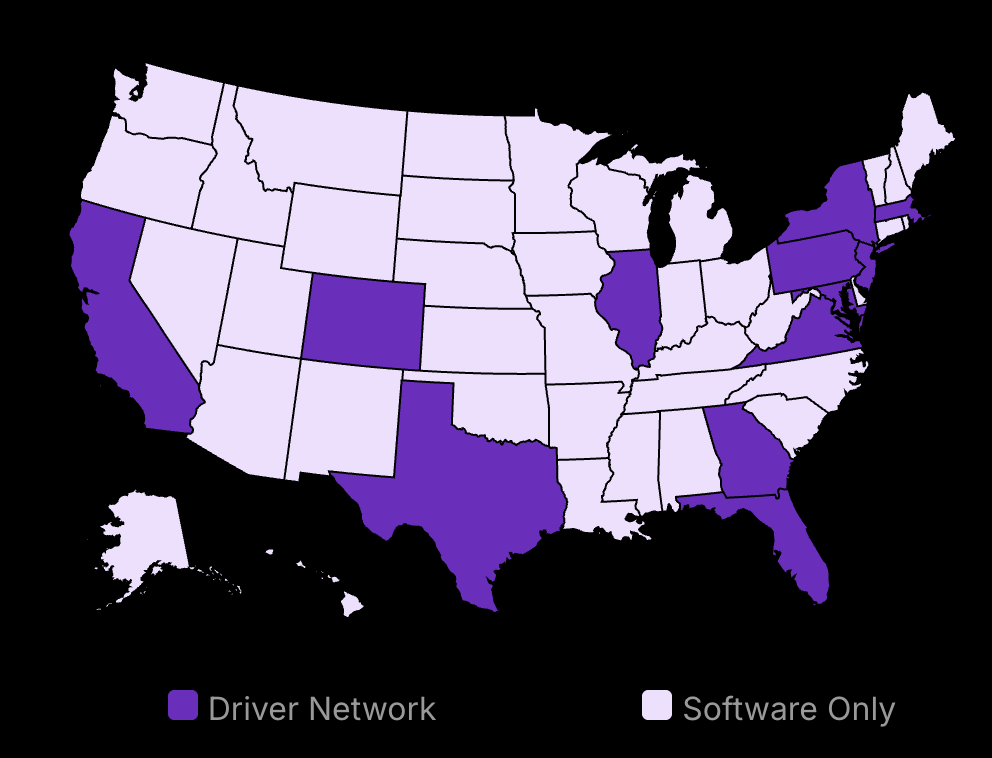

When talking about fast delivery, the strategy often overlooked is the distribution of inventory. Technically, the closer the product is to the customer, the quicker it will arrive. That’s where distributed inventory steps in.

By strategically placing inventory in various locations across different regions, fulfillment centers can reduce delivery times drastically. This seemingly minor alteration culminates in improved customer satisfaction, reduced costs, and a strong competitive edge in the market.

Let’s strip off the irony though. Fast shipping isn’t just about speed. It’s also about precision. It is about the right product reaching the right person, at the right time, and in the right condition. All while maintaining effective communication with customers regarding shipping statuses.

Shipping and delivery are not to be underestimated. They shape customer experiences and imprint brand impressions. Ultimately, they are keys to sealing customer loyalty and defining an ecommerce business i-commerce success.

Technology in Fulfillment Centers: Powering Efficiency and Accuracy

The Use of Automation in Fulfillment Centers

Automation in fulfillment centers isn’t an element of the future – it’s the present. With the influx of online orders, fulfillment centers have been driving towards automation as a way to improve both precision and cost-effectiveness.

First off, automation reduces human error. For example, conveyor belts and automated sorting systems improve inventory management, curbing potential mistakes and shrinkage.

Secondly, automation offers speed. Automated guided vehicles (AGVs), for instance, can expediently move products within the center – an essential aspect when time is key.

Automation also enables scalability. Imagine having to deal with a sudden influx of orders. Automated systems can swiftly scale up or down according to demand, ensuring a smooth flow of operations.

The Human Factor in Automation

Despite the drive for automation, the human aspect is irreplaceable. Humans react better to unforeseen problems and can perform tasks requiring higher-level thinking.

How AI and Machine Learning are Transforming Fulfillment Centers

Artificial intelligence (AI) and machine learning in fulfillment centers are not sci-fi talk – they are realities reshaping the industry. These technologies perform complex tasks, enhance productivity, and optimize processes.

AI and machine learning are critical in predictive analytics, which forecast consumer ordering patterns and thereby streamline inventory management.

Moreover, these technologies are instrumental in working alongside humans. Through AI-powered robotics, humans can delegate mundane tasks, allowing them to focus on more complex tasks requiring critical thinking.

AI and machine learning also take problem-solving to the next level. They use past trends and real-time data to make strategic decisions, revolutionizing supply chain management.

Boosting Business with Integrated Systems 📈

Integrated order processing can significantly increase productivity by 25%, reduce space consumption by 20%, and improve stock use efficiency by 30%.

The Future of AI and Machine Learning in Fulfillment Centers

As AI and machine learning become more sophisticated, their role within fulfillment centers will only escalate. With continuous advancements, these technologies will only get better at improving efficiency and accuracy.

As we continue to unravel the aspects of fulfillment centers, it’s clear that technology is a crucial part of the whole ecommerce fulfillment equation. With automation, AI, and machine learning at the forefront, these centers are effectively addressing the challenges of the ever-expanding e-commerce industry.

Fulfillment Center vs Warehouse: Understanding the Difference

Key Features of a Fulfillment Center

Fulfillment centers emerge as specialized hubs focused on the fulfillment provider handling ecommerce orders. Unlike traditional warehouses -which store goods- fulfillment centers are actively engaged in processing and shipping online purchases, granting an efficient ordering and delivery system. Looking to enhance your online business’s efficiency? Explore top-notch ecommerce order fulfillment services tailored to ensure smooth processing and shipment of your orders.

The cornerstone of a fulfillment center is its ability to synchronize incoming orders with inventory swiftly and accurately. They are typically equipped with integrated software systems to ensure timely service, order processing, and robust customer communication. They also boast varied shipping methods, effectively meeting customer preferences and pressures linked to same-day or expedited delivery requirements. Discover the best practices to enhance accuracy in processing online orders, ensuring that every aspect of ecommerce order precision contributes to overall customer satisfaction.

Fulfillment centers offer a series of key features that help online businesses enhance their service and speedy delivery.

Fast Shipping and Delivery

Fulfillment centers excel in rapid processing and shipping orders. With strategic locations near major shipping carriers, they often guarantee faster order deliveries. Discover how to leverage the Shopify Fulfillment Network for quick deliveries, streamlined tracking, and efficient order processing.

Inventory Management and Tracking

These centers run via modern inventory management systems that track products, manage stock levels, and alert for restocks, ensuring no product runs out of stock. This advanced tracking ensures accuracy in order fulfillment, crucial to an ecommerce store’s success.

How Warehouses Differ from Fulfillment Centers

Warehouses and fulfillment centers are often confused due to their operational overlap. Yet, they serve different roles in the logistics process.

Typically, a warehouse is a large storage facility that stores goods for extended periods. They primarily function as a go-between for manufacturers and retailers, not directly interacting with customers and offering minimal shipping services. Their focus is on storage over speed and efficiency in order dispatch.

Warehouses and Long-Term Storage

Warehouses often house vast quantities of goods for an extended duration. They prove critical when large amounts of product require storage before being distributed to retail locations or fulfillment centers.

Limited Customer Interaction

Warehouses do not commonly engage in direct customer interaction. They are not typically equipped to handle customer orders, process returns, or provide customer service — roles often undertaken by fulfillment centers. Understanding their core differences can give businesses clarity in deciding what type of facility best meets their needs.

The AI & Machine Learning Landscape in Warehousing 🤖

Despite the technological advances, 50.1% of firms only occasionally utilize AI, with 46% not using it at all. However, 19% have seen improved forecast accuracy through machine learning in supply chain projects.

The Impact of Fulfillment Centers on E-commerce

How Fulfillment Centers Support E-commerce Growth

While the brimming potential of your e-commerce site numbs the competition, the ecommerce retailers’ true secret weapon lies behind the delivery truck doors – the fulfillment centers. These bustling hubs of activity are the unsung heroes that drive the turn of the e-commerce cogwheel.

Take a product’s journey, for instance. After consumers make their digital selections, it’s the fulfillment center that processes the order, pulls the product from inventory, packs it, and prepares it for shipping. This intricate dance, when choreographed right, leads to timely delivery and satisfied customers. Discover the fundamentals of ecommerce fulfillment to ensure your online orders are processed and delivered efficiently.

Moreover, fulfillment centers provide the critical capability of handling high-volume orders, ensuring scalability for peak sales periods. A holiday rush or a mega sale? Fulfillment centers are designed to handle these e-commerce surges without breaking a sweat.

The Role of Fulfillment Centers in Customer Satisfaction

An efficient fulfillment center isn’t just good for an ecommerce business’ operations; it’s a key factor in customer satisfaction. Rapid dispatch, accurate order fulfillment, and careful packaging all contribute to a positive customer experience, thereby enhancing brand loyalty. These factors, in essence, ensure repeat business and sustained growth for an e-commerce company.

The Future of Fulfillment Centers in the E-commerce Industry

As we gaze into the 360-degree mirror of e-commerce progression, it’s clear that fulfillment centers are not only a fixture in the current landscape but also a cornerstone of the future.

Driven by advancements in technology, fulfillment centers are becoming smarter, faster, and more efficient. Robotics, AI, and machine learning are automating warehouse processes, driving efficiency and productivity for fulfillment company. Some centers are even experimenting with drone technology, which could revolutionize the delivery process.

The future appears to be one where frictionless commerce is the standard, not the exception. A dynamic own fulfillment center that pivots according to demand flux, seasonality, and real-time data will be vital in achieving this objective.

While we might not have reached the Jetsons age yet, one thing is clear: the nature of fulfillment centers will continue to evolve hand-in-hand with the e-commerce industry. Whether it’s the use of VR for employee training, utilizing sophisticated AI for inventory management, or deploying IoT for real-time tracking, the future of fulfillment is nothing less than extraordinary.

No sign-off or summary is needed.

Cost Concerns in E-commerce Fulfillment 💸

Labor shortages have impacted 77% of online retailers, with 51% experiencing increased fulfillment costs, underscoring the challenges of cost management in operations.

A Peek into the Pulse of Commerce

Navigating the whirlwind of a fulfillment center has never been less of a mystery – from understanding the intense organization, data-based strategies, and critical teamwork involved, it’s clear to see the precision, speed, and dynamism that affect your business.

This insider’s perspective is your advantage – a sneak peek into the heart of commerce. Remember, knowing how a fulfillment center works doesn’t just shape expectations; it optimizes your business decisions, helps improve products, and makes your customer experience smoother.

Now think about how this new understanding can translate into your organization’s operation strategy. Could tweaks in product packaging work better with a fulfillment center’s system? Could syncing up your manufacturing tempo with their stock turnover reduce idle inventory?

Ready to adapt to this new knowledge? Start by examining your online store business model, supply chain system, and packing and shipping costs today. Can they be harmonized with the fulfillment center’s rhythm for a more efficient and cost-effective engagement?

Remember, your enterprise’s success is part of this massive orchestra – every part harmoniously synchronizing with the other, ensuring seamless commerce, and a satisfied customer. How will you conduct your part?