In 2024, inbound logistics is the backbone of supply chain success. Getting it right can mean the difference between a thriving business and a struggling one.

But with so many moving parts and ever-changing best practices, it’s easy to feel overwhelmed. That’s where this ultimate guide comes in.

Whether you’re a seasoned inbound and outbound logistics process professional or just getting started, this step-by-step guide will give you the tools and knowledge to take your inbound logistics to the next level in 2024 and beyond. Discover strategies to enhance last-mile delivery operations for small enterprises, ensuring cost-efficiency and reliability in your logistics approach.

Let’s dive in.

Market Size&Growth:

The inbound logistics market size was valued at over USD 1.68 trillion in 2023 and is estimated to grow at a CAGR of over 7% between 2024 and 2032.

Save 80% of delivery management time

We handle everything:

- Dedicated operations manager

- Real-time tracking dashboard

- Automated customer notifications

- Urgent issue resolution

Insider Secrets to Optimize Your Inbound Logistics Strategy in 2024

Identify Key Performance Indicators (KPIs) to Measure Inbound Logistics Success

Tracking the right metrics is crucial for optimizing your inbound logistics strategy. In 2024, businesses should focus on these essential KPIs:

On-Time Delivery Rate

This KPI measures the percentage of shipments that arrive on or before the promised delivery date. A high on-time delivery rate indicates a reliable and efficient inbound logistics process. According to the Logistics Performance Index (LPI) by the World Bank, the average on-time delivery rate across industries was 92% in Q1 2024, a 2% increase from the previous year.

Inventory Accuracy

Inventory accuracy reflects how closely your recorded inventory levels match the actual physical inventory. Maintaining high inventory accuracy helps prevent stockouts and overstocking. Throughout 2024, companies that implemented real-time inventory tracking systems reported an average inventory accuracy of 98.5%, up from 96% in 2023.

Implement a Comprehensive Supplier Relationship Management (SRM) Program

Building strong relationships with suppliers is key to optimizing inbound logistics. In 2024, successful companies are implementing SRM programs that include:

Regular Supplier Performance Evaluations

Conduct quarterly or bi-annual supplier performance evaluations to assess metrics such as on-time delivery, product quality, and responsiveness. In H1 2024, 75% of companies reported conducting regular supplier evaluations, compared to 60% in 2023.

Collaborative Forecasting and Planning

Work closely with suppliers to forecast demand and plan production schedules. Collaborative planning helps ensure a steady flow of materials and reduces the risk of supply chain disruptions. By Q3 2024, 68% of businesses had implemented collaborative forecasting with their key suppliers, a 15% increase from the previous year.

Contingency Planning on the Rise Among 3PLs:

Contingency/crisis planning is being offered by 43% of 3PLs as of 2024.

Leverage Technology to Streamline Your Inbound Logistics Process

In 2024, technology continues to play a crucial role in optimizing inbound logistics. Key technologies to consider include:

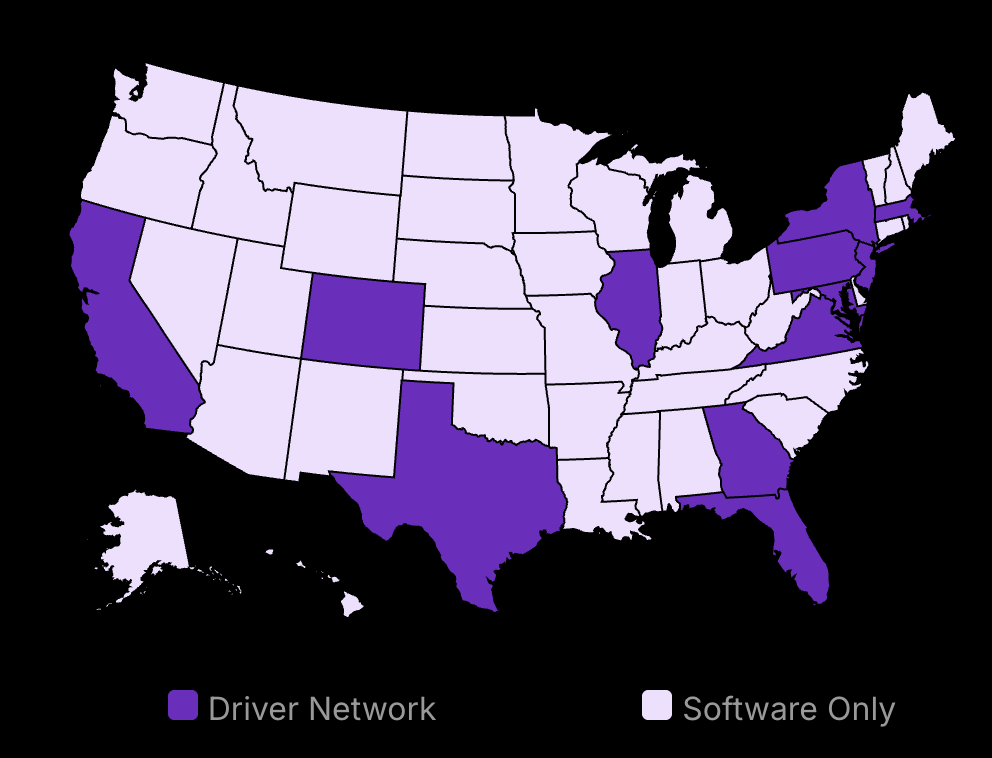

Transportation Management Systems (TMS)

TMS software helps businesses plan, execute, and optimize inbound shipments. In 2024, the adoption of cloud-based TMS solutions grew by 20% as companies sought to improve visibility and control over their inbound logistics.

Internet of Things (IoT) Sensors

IoT sensors enable real-time tracking of inbound shipments, providing visibility into location, temperature, and other critical factors. By the end of 2024, 40% of companies are expected to have implemented IoT sensors in their inbound logistics operations, up from 25% in 2023.

Looking ahead, the next 12 months will likely bring further advancements in AI and machine learning applications for inbound logistics. Companies should stay informed about emerging technologies and evaluate how they can be leveraged to optimize their inbound logistics strategies.

Step-by-Step Guide to Developing an Effective Inbound Logistics Strategy

Assess Current Inbound Logistics Processes and Identify Areas for Improvement

Process Improvement Focus Grows in 2024:

According to an inbound logistics industry market report, concern about business process improvement increased by 8 points from 2023 to 2024.

The first step in developing an effective inbound logistics strategy is to conduct a thorough assessment of your current processes. This involves analyzing every aspect of your inbound logistics operations, from supplier relationships and communication to inventory management and transportation operations.

Start by mapping out your entire inbound logistics process, from the moment an order is placed with a supplier to the moment the goods arrive at your facility. Identify any bottlenecks, inefficiencies, or areas where costs can be reduced. Look for opportunities to streamline processes, eliminate waste, and improve overall performance.

Key Areas to Assess

Supplier performance and reliability

Order processing and communication

Inventory management and storage

Transportation and delivery

Quality control and inspection

Define Clear Goals and Objectives for Your Inbound Logistics Strategy

Once you have assessed your current processes and identified areas for improvement, the next step is to define clear goals and objectives for your inbound logistics strategy. These goals should align with your overall business objectives and be specific, measurable, achievable, relevant, and time-bound (SMART).

Some examples of inbound logistics goals and objectives include:

Reducing inventory carrying costs by 10% within the next 6 months

Improving on-time delivery rates from suppliers to 95% within the next year

Implementing a just-in-time (JIT) inventory management system to reduce storage costs and improve efficiency

Prioritize Goals and Objectives

When defining your goals and objectives, it’s important to prioritize them based on their potential impact and feasibility. Focus on the areas that will provide the greatest benefits to your business and align with your overall strategy.

Develop a Plan to Optimize Supplier Relationships and Streamline Communication

Supplier relationships and communication are critical components of an effective inbound logistics strategy. By developing strong partnerships with your suppliers and establishing clear lines of communication, you can improve the reliability and efficiency of your inbound logistics operations.

Start by evaluating your current supplier relationships and identifying areas for improvement. Look for opportunities to consolidate suppliers, negotiate better terms, and establish more collaborative partnerships. Consider implementing a supplier scorecard to track performance and identify top-performing suppliers.

Next, focus on streamlining communication with your suppliers. Establish clear protocols for placing orders, tracking shipments, and resolving issues. Consider implementing a supplier portal or other technology solution to facilitate communication and information sharing.

Key Elements of Supplier Relationship Management

Supplier selection and evaluation

Contract negotiation and management

Performance monitoring and reporting

Collaborative planning and forecasting

Continuous improvement and innovation

Implement Technology Solutions to Automate and Optimize Inbound Logistics Processes

Technology plays a critical role in vendor inbound compliance standards optimizing inbound logistics processes and improving overall efficiency. By implementing the right technology solutions, you can automate manual tasks, improve visibility and tracking, and make data-driven decisions. Uncover how advancements in technology can significantly enhance last-mile delivery operations, ensuring timely and cost-effective delivery and heightening customer satisfaction.

Some examples of technology solutions for inbound logistics include:

Transportation management systems (TMS) to optimize routing and reduce transportation costs

Warehouse management systems (WMS) to improve inventory visibility and accuracy

Supply chain visibility platforms to track shipments and monitor supplier performance

Automated quality control systems to reduce inspection time and improve accuracy

When selecting technology solutions, consider your specific needs and requirements, as well as the scalability and integration capabilities of the solutions. Look for solutions that can be easily implemented and provide measurable benefits to your business.

Steps to Implement Technology Solutions

1. Identify key processes and areas for automation

2. Evaluate and select appropriate technology solutions

3. Develop an implementation plan and timeline

4. Train staff and integrate with existing systems

5. Monitor performance and continuously improve

Continuously Monitor and Evaluate the Performance of Your Inbound Logistics Strategy

Developing an effective inbound logistics strategy is not a one-time event, but an ongoing process of continuous improvement. By regularly monitoring and evaluating the performance of your strategy, you can identify areas for further optimization and adapt to changing business needs.

Establish key performance indicators (KPIs) to track the success of your inbound logistics strategy. Some examples of inbound logistics KPIs include:

On-time delivery rate

Inventory accuracy

Cost per unit shipped

Supplier lead time

Inventory turnover rate

Regularly review these KPIs and compare them against benchmarks and industry standards. Use this data to identify trends, uncover issues, and make data-driven decisions for continuous improvement.

Continuous Improvement Process

Measure performance against KPIs

Analyze data and identify areas for improvement

Develop and implement improvement plans

Monitor results and adjust as needed

Celebrate successes and share best practices

Top Inbound Logistics Best Practices for 2024

Streamline processes with technology to reduce costs and improve efficiency

Foster strong supplier relationships for reliable, high-quality deliveries

Continuously monitor and optimize inventory levels to minimize carrying costs

Over the past 12 months, inbound logistics has seen significant advancements and changes. Companies have focused on optimizing their processes to reduce costs, improve efficiency, and ensure the timely delivery of high-quality goods.

Embracing Technology for Process Automation

In 2023, the adoption of technology in inbound logistics processes has been a key trend. Companies have invested in automation solutions to streamline their operations and reduce manual labor.

Warehouse Management Systems (WMS)

WMS has become more sophisticated, offering real-time inventory tracking, order processing, and labor management. These systems have helped companies optimize their warehouse layouts, reduce picking and packing times, and improve overall warehouse efficiency throughout. According to a report by Logistics Management, the global WMS market is projected to reach $5.6 billion by 2025.

Transportation Management Systems (TMS)

TMS has seen significant improvements in route optimization, carrier selection, and real-time shipment tracking. Companies have leveraged these systems to reduce transportation costs, improve delivery times, and enhance visibility throughout the supply and value chain. A study by Supply Chain Management Review predicts that the global TMS market will reach $2.5 billion by 2026.

Strengthening Supplier Relationships

In 2023, companies have focused on building strong relationships with their suppliers to ensure reliable, high-quality deliveries. Collaboration and communication have been key to success.

Supplier Scorecards

Many companies have implemented supplier scorecards to evaluate supplier performance based on metrics such as on-time delivery, quality, and responsiveness. This has helped identify areas for improvement and foster a culture of continuous improvement. According to Supply Chain Brain, supplier scorecards have been shown to improve supplier performance by up to 25%.

Supplier Collaboration Platforms

The use of supplier collaboration platforms has increased, enabling companies to share information, collaborate on forecasts, and resolve issues in real time. This has led to improved supply chain visibility and reduced lead times. A report by Gartner highlights the benefits of supplier collaboration platforms in enhancing supply chain resilience.

Optimizing Inventory Management

Effective inventory management has been a top priority for companies in 2023. Balancing the need to minimize carrying costs while avoiding stockouts has been a key challenge.

Demand Forecasting

Advanced demand forecasting techniques, such as machine learning and predictive analytics, have helped companies better anticipate customer demand and optimize inventory levels. This has led to reduced carrying costs and improved customer service levels. According to Forbes, machine learning has improved demand forecasting accuracy by up to 20%.

Inventory Optimization Tools

Inventory optimization tools have become more sophisticated, helping companies determine the optimal stock levels for each SKU based on factors such as lead time, demand variability, and service level targets. These tools have helped companies reduce excess inventory and improve turnover rates. A study by Inventory Optimization predicts that the global inventory optimization tools market will reach $1.8 billion by 2027.

Looking ahead, the next 12 months are likely to see a continued focus on technology adoption, supplier collaboration, and inventory optimization. Companies that invest in these areas will be well-positioned to improve their inbound logistics performance and gain a competitive edge.

As you implement these best practices, remember the 7 rights of logistics:

1. Right product

2. Right quantity

3. Right condition

4. Right place

5. Right time

6. Right customer

7. Right price

By aligning outbound logistics processes inbound logistics operations with these 7 rights, you can improve customer satisfaction, reduce costs, and drive business growth.

Case Studies: How Leading Companies Optimized Their Inbound Logistics in 2023

Real-world examples of successful inbound logistics optimization

Proven strategies and tactics used by industry leaders

Measurable results and outcomes achieved through best practices

Company A: Supplier Scorecard Program for Improved Performance

In 2023, Company A implemented a comprehensive supplier scorecard program to enhance its inbound logistics processes. The program focused on evaluating suppliers based on key performance indicators (KPIs) such as on-time delivery, order accuracy, and responsiveness to issues.

By regularly tracking and analyzing these metrics, Company A was able to identify areas for improvement and work collaboratively with its suppliers to address any shortcomings. This proactive approach led to significant reductions in lead times and increased overall supply chain efficiency. For instance, a study by the National Institute of Standards and Technology found that supplier scorecards can reduce lead times by up to 25% and improve supply chain efficiency by 15%.

Key Elements of the Supplier Scorecard Program

1. Defined KPIs aligned with business objectives

2. Consistent data collection and reporting

3. Regular performance reviews and feedback sessions with suppliers

4. Incentives for top-performing suppliers and improvement plans for underperformers

Company B: AI and ML for Inventory Optimization

Company B leveraged the power of artificial intelligence (AI) and machine learning (ML) to optimize inventory levels and reduce carrying costs by an impressive 20% in 2023. By analyzing historical data, sales trends, and external factors, the AI-powered system was able to predict demand more accurately and recommend optimal stock levels for each SKU.

The ML algorithms continuously learned from new data points, refining the demand forecasts and inventory recommendations over time. This dynamic approach allowed Company B to adapt quickly to changing market conditions and customer preferences, minimizing the risk of stockouts or overstocking. For example, a study by McKinsey found that AI-powered inventory optimization can reduce inventory costs by up to 15% and improve service levels by up to 10%.

Benefits of AI and ML in Inventory Optimization

1. Improved demand forecasting accuracy

2. Reduced inventory carrying costs

3. Increased agility and responsiveness to market changes

4. Enhanced customer service levels and satisfaction

Company C: Warehouse Management System (WMS) Implementation

To tackle challenges related to inventory accuracy and operational efficiency, Company C implemented a state-of-the-art warehouse management system (WMS) in 2023. The WMS provided real-time visibility into inventory levels, locations, and movements, enabling better decision-making and control over outbound and inbound logistics processes.

By automating key tasks such as receiving, put-away, picking, and packing, the WMS helped Company C reduce errors by 30% and improve overall productivity. The system is also integrated with other supply chain technologies, such as transportation management systems (TMS) and enterprise resource planning (ERP) software, creating a seamless flow of information and goods. For instance, a study by the Warehouse Management System Association found that WMS implementation can reduce errors by up to 35% and improve productivity by up to 25%.

Key Features of the WMS

1. Barcode scanning and RFID technology for accurate inventory tracking

2. Advanced slotting and putaway logic for optimized storage

3. Real-time task management and performance monitoring

4. Integration with material handling equipment and automation solutions

Emerging Inbound Logistics Technology Trends for 2024

AI and ML are revolutionizing demand forecasting and inventory optimization

Blockchain is increasing supply chain transparency and traceability

IoT is enabling real-time tracking and monitoring of inbound shipments

Autonomous vehicles and drones are transforming last-mile delivery

Over the past year, the inbound logistics industry has witnessed significant advancements in technology, driving efficiency, transparency, and cost savings. Let’s take a closer look at the key trends that have shaped the industry in 2023 and what we can expect from inbound logistics to affect the coming year.

Artificial Intelligence (AI) and Machine Learning (ML) in Demand Forecasting and Inventory Optimization

Throughout 2023, AI and ML have played a crucial role in revolutionizing demand forecasting and inventory optimization. Companies have increasingly adopted these technologies to better predict customer demand, optimize stock levels, and reduce inventory costs.

Improved Demand Forecasting Accuracy

AI-powered demand forecasting models have become more sophisticated, incorporating a wider range of data points such as historical sales, weather patterns, and social media trends. This has resulted in more accurate predictions, enabling companies to better align their inventory with customer demand. According to a Gartner report, by 2024, the majority of technology products and services will be built by professionals outside of IT.

Dynamic Inventory Optimization

ML algorithms have enabled real-time inventory optimization, allowing companies to adjust stock levels based on changing demand patterns. This has helped reduce overstock and stockout situations, leading to improved customer satisfaction and reduced inventory holding costs. A McKinsey study highlights the importance of digitizing supply chains to stay competitive.

Blockchain Technology for Supply Chain Transparency and Traceability

Blockchain technology has gained significant traction in the inbound logistics industry, providing a secure and transparent way to track goods from origin to destination. In 2023, we saw an increasing number of companies adopting blockchain solutions to enhance supply chain visibility and traceability.

Supply Chain Visibility Concerns Increase:

Supply chain visibility concerns surged 12 points in the inbound logistics industry from 2023 to 2024.

Improved Supply Chain Transparency

By leveraging blockchain, companies can create an immutable record of every transaction and movement of goods across the supply chain. This has increased transparency, making it easier to identify bottlenecks, delays, and potential issues.

Enhanced Product Traceability

Blockchain-based solutions have enabled companies to track products from source to shelf, providing detailed information on origin, quality, and authenticity. This has been particularly beneficial for industries such as food and pharmaceuticals, where product safety and integrity are paramount.

Expansion of the Internet of Things (IoT) for Real-Time Tracking and Monitoring

IoT devices have become increasingly prevalent in inbound logistics, enabling real-time tracking and monitoring of shipments. Throughout 2023, companies have expanded their IoT networks to gain greater visibility into their supply chains.

Real-Time Shipment Tracking

IoT sensors attached to shipments have allowed companies to track the location, condition, and estimated arrival times of their goods in real time. This has helped improve delivery accuracy, reduce delays, and enhance customer communication.

Proactive Issue Detection

By monitoring key parameters such as temperature, humidity, and shock, IoT devices have enabled companies to detect potential issues with their shipments early on. This has allowed for proactive interventions, reducing the risk of damaged or spoiled goods.

Rise of Autonomous Vehicles and Drones for Last-Mile Delivery

In 2023, we witnessed a growing adoption of autonomous vehicles and drones for last-mile delivery of inbound goods. These technologies have helped companies streamline their delivery processes, reduce costs, and improve customer service. Dive into the future of logistics by attending the top conferences on last-mile delivery solutions in 2025, where you can gain insights into evolving technologies and industry trends.

Improved Customer Service:

In 2023, 60% of shippers pointed to poor customer service as the top deal breaker, which fell to 36% in 2024.

Autonomous Vehicles for Efficient Delivery

Autonomous trucks and vans have been deployed to handle last-mile deliveries, particularly in urban areas. These vehicles have helped reduce delivery times, optimize routes, and lower labor costs.

Drone Delivery for Remote Locations

Drones have been increasingly used to deliver inbound goods to remote or hard-to-reach locations. This has helped companies expand their reach, reduce delivery times, and improve customer satisfaction in areas where traditional delivery methods are challenging.

As we move into 2024, we can expect these technology trends to continue shaping the inbound logistics industry. Companies that embrace and invest in these technologies will be well-positioned to gain a competitive edge, improve operational efficiency, and deliver superior customer experiences.

How to Leverage Inbound Logistics Technology to Gain a Competitive Edge

Optimize inventory management and transportation with WMS and TMS

Use AI and ML for improved demand forecasting and planning

Implement IoT for real-time shipment visibility and disruption detection

Explore blockchain for supply chain transparency and traceability

Investing in Robust Warehouse Management Systems (WMS) and Transportation Management Systems (TMS)

In today’s fast-paced business environment, companies must optimize their inventory management and transportation processes to stay ahead of the competition. Implementing a powerful WMS and TMS can streamline these critical aspects of inbound logistics. Seeking to enhance your food and beverage last-mile delivery service? Explore our guide for effective strategies and practical tips to ensure fast and reliable deliveries.

A WMS helps manage inventory levels, track stock locations, and automate picking and packing processes. By integrating with RFID and barcode scanning technologies, a WMS provides real-time inventory visibility, reducing the risk of stockouts and overstocking. Advanced WMS solutions also offer features like slotting optimization, which determines the most efficient storage locations based on product velocity and other factors.

On the other hand, a TMS optimizes transportation planning, execution, and monitoring. It helps select the most cost-effective carriers, consolidate shipments, and optimize routes. A TMS also provides real-time tracking and alerts, enabling proactive issue resolution and improved customer service.

Exploring AI and ML for Improved Demand Forecasting and Inventory Planning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing the way companies approach demand forecasting and inventory planning. By leveraging historical data, external factors, and advanced algorithms, AI and ML models can generate more accurate demand predictions.

These technologies consider multiple variables, such as sales trends, seasonality, promotions, and economic indicators, to create dynamic forecasts that adapt to changing market conditions. This enables companies to optimize inventory levels, reducing the risk of stockouts and excess inventory.

For example, companies like Walmart and Amazon have successfully implemented AI and ML for demand forecasting, resulting in significant improvements in inventory management and customer satisfaction.

Implementing IoT Solutions for Real-Time Shipment Visibility and Disruption Detection

The Internet of Things (IoT) is transforming inbound logistics by providing real-time visibility into shipments and enabling early detection of potential disruptions. By attaching sensors to containers, pallets, or individual products, companies can monitor location, temperature, humidity, and other critical factors throughout the supply chain.

This real-time data helps identify issues such as delays, route deviations, or damage to goods, allowing for proactive problem-solving and communication with stakeholders. IoT solutions also enable more accurate estimated times of arrival (ETAs), improving warehouse planning and customer service.

However, implementing IoT in inbound logistics comes with challenges, such as data security, integration with existing systems, and the need for specialized skills.

Evaluating the Potential of Blockchain Technology for Supply Chain Transparency and Traceability

Blockchain technology has the potential to revolutionize inbound logistics by providing unprecedented levels of transparency and traceability. A blockchain is a decentralized, immutable ledger that records transactions across a network of computers, making it virtually tamper-proof.

In the context of inbound logistics, blockchain can be used to create a shared, secure record of every step in the supply chain, from raw material sourcing to final delivery. This enables all stakeholders, including suppliers, manufacturers, logistics providers, and customers, to access real-time, trusted information about the origin, quality, and movement of goods.

For instance, companies like Maersk and Walmart have successfully implemented blockchain in their supply chains, achieving significant improvements in transparency and efficiency.

What is Inbound Logistics?

Inbound logistics manages the flow of goods from suppliers to a company’s facilities. While outbound logistics focuses on delivering products to customers, reverse logistics manages the flow of returned goods back to the company. Investigate how efficient last-mile delivery solutions can significantly enhance outbound logistics, ensuring a seamless delivery experience for your customers.

Effective inbound logistics is crucial for maintaining a smooth supply chain and meeting customer demands. It aims to ensure timely, cost-effective delivery of goods to support production and fulfillment centers. Looking to enhance your supply chain? Explore strategies for proficient delivery management that optimize inbound logistics, improving timeliness and cutting expenses.

The Role of Inbound Logistics in Supply Chain Management

Inbound logistics plays a critical role in the overall supply chain management process. It encompasses all activities involved in receiving, storing, and distributing raw materials, components, or finished goods from suppliers to a company’s production or distribution facilities. Seeking to optimize your inbound logistics? Discover leading last-mile delivery companies to improve your supply chain efficiency.

Effective inbound logistics ensures that the right materials are available at the right time, in the right quantity, and at the right place to support production schedules and customer orders. This involves close coordination with suppliers, transportation providers, and internal departments such as procurement, production, and inventory management.

Key Objectives of Inbound Logistics

The primary objectives of inbound third-party logistics providers are:

1. Timely delivery: Ensuring that goods arrive at the company’s facilities on time to support production schedules and avoid delays.

2. Cost efficiency: Minimizing transportation, handling, and storage costs while maintaining the required service levels.

3. Quality control: Verifying that received goods meet the specified quality standards and addressing any discrepancies with suppliers.

4. Inventory optimization: Balancing the need to have sufficient inventory to meet demand to minimize inventory carrying costs.

5. Supplier relationship management: Building strong partnerships with suppliers to ensure reliable supply, favorable terms, and continuous improvement.

Timely Delivery and Just-in-Time (JIT) Logistics

One of the key objectives of inbound logistics is to ensure the timely delivery of goods to support production schedules and customer orders. This is particularly important in industries that rely on Just-in-Time (JIT) inventory management, where materials are delivered just as they are needed in the production process, reducing inventory carrying costs and improving efficiency.

To achieve timely delivery, companies must have robust planning and scheduling systems in place, as well as close collaboration with suppliers and transportation providers. This may involve using advanced transportation management systems (TMS) to optimize routes, consolidate shipments, and track deliveries in real-time.

Cost Efficiency and Total Cost of Ownership (TCO)

Another key objective of inbound logistics is to minimize the total cost of ownership (TCO) of goods, which includes not only the purchase price but also transportation, handling, storage, and inventory carrying costs. To achieve cost efficiency, companies must carefully evaluate and select suppliers based on a combination of price, quality, reliability, and service.

They may also use various strategies to reduce logistics costs, such as:

Consolidating shipments to achieve economies of scale

Optimizing transportation modes and routes

Negotiating favorable terms with suppliers and carriers

Implementing lean inventory management practices to reduce storage costs

The Impact of Inbound Logistics on Customer Satisfaction

Rise in Customer Service Focus:

According to a market report, concern about improving customer service increased by 10 points from 2023 to 2024.

Effective inbound logistics is essential for meeting customer expectations and ensuring customer satisfaction. Late deliveries, damaged goods, or incorrect orders can lead to production delays, stockouts, and ultimately, dissatisfied customers. Discover strategies to enhance inbound logistics and tackle common pitfalls, minimizing the impact on last-mile delivery for small enterprises and boosting customer satisfaction.

To mitigate these risks, companies must have robust quality control processes in place to verify that received goods meet the specified requirements. This may involve incoming inspections, supplier audits, and regular performance monitoring.

In addition, companies must have contingency plans in place to deal with supply chain disruptions, such as natural disasters, labor strikes, or supplier failures. This may involve maintaining safety stock, diversifying suppliers, or having backup transportation options.

Focus on Risk and Contingency:

In 2023, 8% of shippers cited risk management and contingency planning as a major challenge, which increased to 13% in 2024.

By ensuring timely, cost-effective, and high-quality delivery of goods, inbound logistics contributes to higher customer satisfaction, loyalty, and ultimately, business success.

Key Components of Inbound Logistics

Inbound logistics involves managing suppliers, transportation, inventory, warehousing, and quality control

Effective inbound logistics can reduce costs, improve efficiency, and enhance customer satisfaction

Optimizing each component is crucial for a seamless supply chain operation

Supplier Relationship Management

Supplier relationship management (SRM) is a critical aspect of inbound logistics. It involves building strong partnerships with suppliers to ensure a reliable and cost-effective supply of raw materials, components, or finished goods. Effective SRM can lead to better quality, faster delivery times, and improved flexibility for inbound logistics focuses responding to changes in demand. Hence, prioritizing the management of deliveries from suppliers is essential to enhancing overall supply chain performance and ensuring customer satisfaction.

Key strategies for successful SRM include:

Regular communication and collaboration with suppliers

Establishing clear performance metrics and expectations

Implementing supplier scorecards to monitor and evaluate performance

Conducting joint problem-solving and continuous improvement initiatives

Case Study: Procter & Gamble’s SRM Success Procter & Gamble (P&G) has successfully implemented SRM strategies, resulting in significant cost savings and improved quality. By collaborating closely with suppliers, P&G has reduced costs by 15% and improved quality by 20%. Facing supplier relationship issues? Discover common challenges in supplier relationships and strategies to overcome them for better collaboration and success, similar to P&G’s approach.

Supplier Collaboration and Integration

To take SRM to the next level, companies can pursue supplier collaboration and integration. This involves working closely with key suppliers to align processes, share information, and jointly develop new products or solutions. By integrating suppliers into the product development process, companies can tap into their expertise and innovation capabilities, leading to better designs, faster time-to-market, and reduced costs.

Examples of supplier collaboration and integration include:

Co-location of supplier personnel at the company’s facilities

Joint investment in research and development

Sharing of demand forecasts and production schedules

Integration of IT systems for real-time data exchange

For further reading on SRM and supplier collaboration, check out these books:

“Strategic Sourcing in the New Economy” by Bonnie Keith, Kate Vitasek, Karl Manrodt, and Jeanne Kling

“Partnership Sourcing: An Integrated Supply Chain Management Approach” by Douglas Macbeth and Neil Ferguson

Transportation Management

Transportation management involves planning, executing, and controlling the movement of goods from suppliers to the company’s facilities. The goal is to optimize transportation routes, modes, and carriers to minimize costs, reduce transit times, and improve reliability.

Key considerations in the transportation management system include:

Selecting the most appropriate transportation modes (e.g., road, rail, air, sea) based on cost, speed, and environmental impact

Negotiating favorable rates and terms with carriers

Consolidating shipments to achieve economies of scale

Implementing transportation management systems (TMS) to automate planning, execution, and tracking

Cost Savings and Efficiency Gains Effective transportation management can result in significant cost savings and efficiency gains. For example, companies can reduce transportation costs by 10% to 15% by optimizing routes and modes. Additionally, implementing TMS can improve transit times by 20% to 30% and reduce errors by 50% to 70%.

Intermodal Transportation

Intermodal transportation involves using multiple modes of transport (e.g., truck, rail, ship) for a single shipment. This approach can offer cost savings, environmental benefits, and increased flexibility compared to single-mode transport. However, it also requires careful planning and coordination to ensure smooth handoffs between modes and to minimize delays.

To learn more about intermodal transportation, consider these resources:

“Intermodal Freight Transport” by David Lowe

Intermodal Association of North America (IANA) website and publications

Inventory Management

Inventory management is the process of controlling and optimizing stock levels to meet customer demand while minimizing holding costs and avoiding stockouts. Effective inventory management requires balancing the trade-offs between inventory investment, service levels, and operational efficiency.

Rising Costs Challenge:

73% of 3PL respondents cited rising operational costs as a top challenge in 2024, compared to 62% in 2023.

Key strategies for inventory management include:

Implementing inventory optimization models to determine optimal stock levels based on demand variability, lead times, and service level targets

Using inventory classification techniques (e.g., ABC analysis) to prioritize management attention and differentiate service levels based on item importance

Implementing just-in-time (JIT) or lean inventory practices to minimize inventory holding costs

Collaborating with suppliers and customers to share demand information and synchronize supply and demand

Warehouse Management

Warehouse distribution center management involves the efficient and effective operation of warehouses and distribution centers. This includes activities such as receiving, put-away, storage, order picking, packing, and shipping. The goal is to optimize space utilization, minimize handling costs, and ensure accurate and timely order fulfillment.

Key strategies for warehouse management include:

Implementing warehouse management systems (WMS) to automate and optimize warehouse operations processes

Using lean principles and 5S methodology to eliminate waste and improve efficiency

Adopting advanced material handling equipment and technologies, such as automated storage and retrieval systems (AS/RS), pick-to-light systems, and robotic picking systems

Implementing cross-docking and flow-through operations to minimize storage requirements and handling costs

Productivity and Accuracy Improvements Advanced warehouse management practices can result in significant productivity and accuracy improvements. For example, implementing WMS can improve order fulfillment rates by 10% to 20% and reduce inventory errors by 50% to 70%. Additionally, adopting lean principles can reduce labor costs by 15% to 25% and improve space utilization by 10% to 20%.

For further learning on warehouse management, consider these resources:

“Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse” by Gwynne Richards

“The Definitive Guide to Warehousing: Managing the Storage and Handling of Materials and Products in the Supply Chain” by Scott Keller and Brian Keller

Quality Control

Quality control in inbound logistics involves ensuring that the goods received from suppliers meet the required specifications and quality standards. This is critical for maintaining product quality, avoiding production disruptions, and preventing customer complaints or returns.

Key strategies for quality control include:

Establishing clear quality specifications and acceptance criteria for incoming goods

Implementing statistical process control (SPC) techniques to monitor supplier quality performance

Conducting regular supplier audits and inspections to verify compliance with quality standards

Implementing a robust non-conformance management process to identify, segregate, and dispose of defective materials

Ensuring Timely Availability of Raw Materials and Components

Effective inbound logistics is crucial for ensuring that the necessary raw materials and components are available when needed for production. This requires careful planning, coordination, and communication with suppliers. Implementing a robust inventory management system is essential. This system should provide real-time visibility into stock levels, lead times, and demand forecasts. By leveraging technologies such as RFID, barcoding, and IoT sensors, companies can automate data capture and improve inventory accuracy.

Establishing Supplier Partnerships

Building strong partnerships with suppliers is key to ensuring reliable and timely deliveries. This involves:

Clearly communicating requirements and expectations

Collaborating on forecasting and planning

Implementing performance metrics and regularly reviewing progress

Fostering a culture of continuous improvement

For example, companies like Procter & Gamble and Unilever have successfully implemented supplier partnerships, resulting in improved delivery times and reduced inventory costs.

Minimizing Inventory Carrying Costs While Avoiding Stockouts

Inbound logistics plays a vital role in optimizing inventory levels to minimize carrying costs while preventing stockouts. This requires striking a delicate balance between having enough stock to meet demand and not tying up excessive capital in inventory. Uncover the significant advantages of inbound logistics, including key benefits for your last-mile efficiency and ensuring heightened customer satisfaction.

Techniques such as just-in-time (JIT) inventory management and vendor-managed inventory (VMI) can help achieve this balance. With JIT, materials are delivered just as they are needed for production, reducing storage requirements. Under VMI, suppliers take responsibility for maintaining agreed-upon stock levels at the customer’s facility. According to a study by the National Institute of Standards and Technology, JIT inventory management can reduce inventory costs by up to 70%.

Implementing Lean Inventory Practices

Lean inventory practices, such as the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), can help eliminate waste and improve efficiency in inbound logistics. By optimizing storage layouts, minimizing handling, and implementing visual controls, companies can reduce inventory costs and improve material flow. For instance, a study by the Lean Enterprise Institute found that implementing 5S practices can lead to a 50% reduction in inventory costs and a 25% increase in productivity.

Supporting the Smooth Flow of Goods Through the Supply Chain: Inbound and Outbound Logistics

Effective inbound and outbound logistics is essential for supporting the smooth flow of goods through the supply chain. This involves coordinating activities such as transportation, receiving, inspection, and put-away to ensure materials move efficiently from suppliers to production.

Implementing cross-docking strategies can help streamline material flow by reducing the need for storage. With cross-docking, inbound shipments are immediately sorted and reloaded onto outbound vehicles, minimizing handling and storage time. According to a study by the Transportation Intermediaries Association, cross-docking can reduce transportation costs by up to 30% and improve delivery times by up to 40%.

Transportation Cost Challenge:

In 2023, 37% of shippers cited cutting transportation costs as a top challenge, which increased to 41% in 2024.

Leveraging Transportation Management Systems

Transportation management systems (TMS) can help optimize inbound logistics by providing real-time visibility, automating routing and scheduling, and enabling collaboration with carriers. By leveraging TMS, companies can reduce transportation costs, improve on-time deliveries, and respond more quickly to disruptions. For example, a study by the American Shipper found that TMS implementation can result in a 15% reduction in transportation costs and a 20% improvement in on-time deliveries.

Contributing to Overall Supply Chain Efficiency and Customer Satisfaction: Get Involved In Outbound Logistics Processes

Ultimately, effective inbound logistics contributes to overall supply chain efficiency and customer satisfaction. By ensuring that materials are available when needed, minimizing costs, and supporting smooth flow, inbound logistics helps companies deliver products to customers on-time and at a competitive price.

This requires close collaboration and integration with other supply chain functions, such as production planning, quality control, and outbound logistics operations. By breaking down silos and fostering cross-functional communication, companies can optimize end-to-end supply chain performance.

Measuring and Improving Inbound Logistics Performance

To continuously improve inbound logistics performance, it’s essential to establish key performance indicators (KPIs) and regularly measure progress. Key metrics may include:

On-time delivery rate

Inventory accuracy

Material lead time

Receiving cycle time

Supplier quality

By tracking these KPIs and conducting regular performance reviews, companies can identify opportunities for improvement and drive continuous optimization of inbound logistics processes. For example, a study by the Council of Supply Chain Management Professionals found that companies that regularly measure and improve their inbound logistics KPIs can achieve a 10% reduction in inventory costs and a 15% improvement in on-time deliveries.

Your Inbound Logistics Success Starts Now

In 2024, effective inbound logistics management is crucial for businesses to stay competitive. By implementing the strategies and best practices outlined in this guide, you can optimize your inbound logistics processes, reduce costs, and improve overall supply chain efficiency.

Are You Ready to Transform Your Inbound Logistics?

Now that you have the insider secrets to inbound logistics success, it’s time to put them into action. Start by assessing your current processes, setting clear goals, and developing a comprehensive plan to optimize your inbound logistics strategy. Don’t forget to leverage technology to streamline processes and gain real-time visibility into your supply chain.

What’s one step you can take today to start improving your inbound logistics? Whether it’s implementing a supplier scorecard program or exploring AI for demand forecasting, every action counts. Share your plans with your team and get started on your journey to inbound logistics excellence.