In 2024, a warehouse is more than a storage space. It’s a battlefield where safety and efficiency wage a constant war. As a business owner, you’re the general, and your choices can mean the difference between victory and catastrophic defeat.

Picture this: A bustling warehouse floor, forklifts weaving between towering shelves, workers darting to and fro. It’s a scene of productivity, but beneath the surface lurks an invisible enemy – the threat of accidents and injuries.

The stakes? Higher than you might think. In 2023 alone, warehouse accidents cost U.S. businesses over $7 billion in direct costs, according to the National Safety Council. That’s not counting the human toll of pain, suffering, and lost potential.

But here’s the twist: The most dangerous element in your warehouse isn’t faulty equipment or slippery floors. It’s complacency. The false belief that “it won’t happen here” is the silent killer that turns safe spaces into disaster zones.

So, what’s the solution? A radical shift in how we approach warehouse safety. Forget the outdated checklists and half-hearted safety meetings. It’s time for a revolution in risk management that turns every employee into a safety superhero and transforms your warehouse into an impenetrable fortress of productivity.

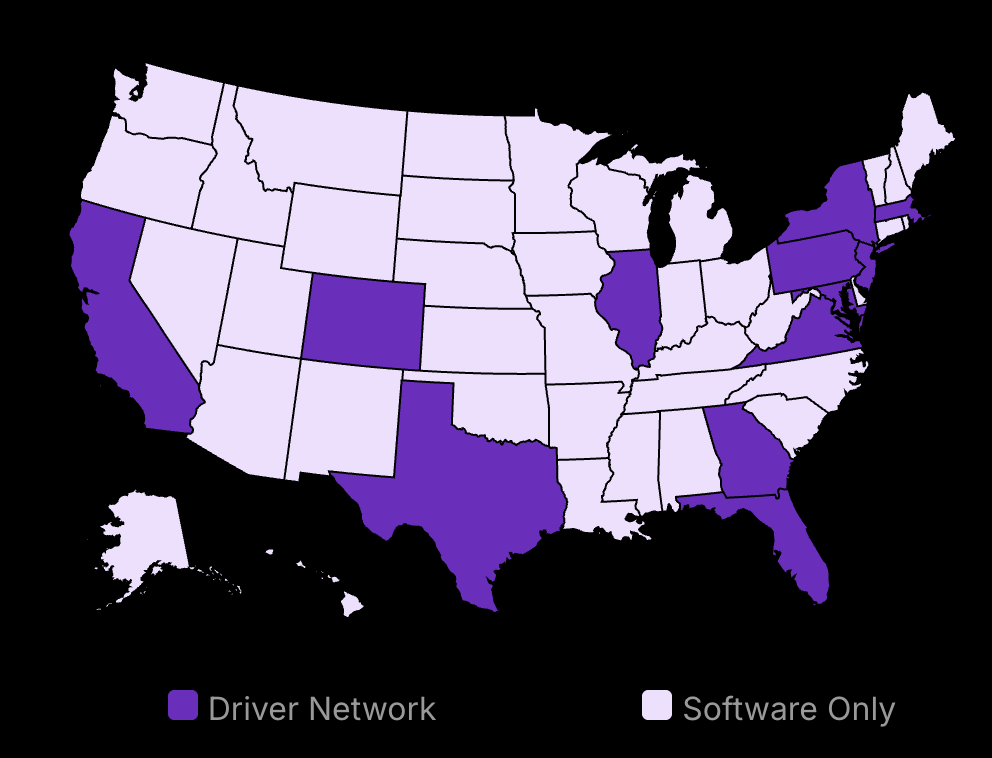

27% higher customer satisfaction

Professional delivery features:

- Real-time GPS tracking

- Automated ETA updates

- Delivery confirmation photos

- 27% higher delivery satisfaction

Essential Warehouse safety tips for 2024

-

Establish clear Standard Operating Procedures.

-

Keep the workplace clean and organized.

-

Use the right Personal Protective Equipment.

Implement Standard Operating Procedures (SOPs)

Defining SOPs is crucial for warehouse safety. SOPs are a set of step-by-step instructions to help warehouse workers carry out complex tasks. They are the blueprint for efficiency and safety. SOPs should cover each job and ensure everyone knows what to do and how to do it safely.

-

Define Detailed Protocols for Each Task

-

Start by mapping out every task in the warehouse. List what each task requires and how it should be done safely.

-

Write detailed instructions for each process, covering the “who, what, where, and how.”

-

Incorporate safety checks within each procedure. For example, include steps to check equipment before use.

-

-

Train Employees on SOPs

-

Hold training sessions for all staff to make sure everyone understands the SOPs.

-

Use simulations or role-playing exercises to practice SOPs in a controlled environment.

-

Regularly review and update the SOPs to reflect any changes in regulations or processes.

-

Maintain a Clean and Organized Workspace

A clean and tidy workspace reduces accidents and helps maintain efficiency. Ensuring that the various warehouse equipment is organized can make a significant difference in day-to-day operations.

-

Regularly Scheduled Cleaning

-

Set up a cleaning schedule for the entire warehouse to minimize debris and obstacles.

-

Assign cleaning tasks to specific team members and rotate these duties to ensure everyone contributes.

-

Use checklists to track what areas need attention and ensure they are not missed.

-

-

Clear Labeling of Storage Areas

-

Label everything clearly, from shelves to bins. This helps workers find what they need without unnecessary searching.

-

Use color-coded labels for different categories of items, making it easy to spot where things belong.

-

Keep frequently used items within easy reach to prevent unnecessary climbing or stretching.

-

Use Personal Protective Equipment (PPE)

PPE acts as the last line of defense against hazards. It includes items like helmets, gloves, and even safety shoes and protective eyewear. Proper use of PPE can significantly reduce the risk of injuries.

To further enhance the safety culture within your operation, consider familiarizing yourself with some essential tips for preserving warehouse safety. These tips encapsulate the key strategies that can transform your approach and lead to significant improvements in accident prevention and compliance.

-

Ensure Correct PPE is Available

-

Assess each task for potential hazards and supply appropriate PPE.

-

Have a PPE station where workers can easily access equipment as they need it.

-

Maintain an inventory of PPE to avoid shortages, and replace worn or damaged items immediately.

-

-

Training on PPE Usage and Maintenance

-

Conduct training sessions on the correct use of each type of PPE.

-

Show how to wear PPE properly and demonstrate maintenance routines to keep equipment effective.

-

Regularly inspect PPE for wear and tear to ensure ongoing protection.

-

Warehouse Risk Management Strategies

-

Reduce accidents by spotting risks early.

-

Respond fast to incidents to minimize impact.

-

Boost safety using advanced technology.

Conduct Regular Risk Assessments

Consistent risk assessments are the backbone of a safe warehouse. They help spot dangers before they cause problems.

Schedule Weekly Inspections

-

Create an Inspection Calendar: Assign specific days each week for these checks. Mondays work well because they set the tone for the week.

-

Form a Task List: List areas and equipment to check. Include aisles, storage areas, and all machinery.

-

Assign Responsibilities: Have trained personnel conduct inspections. Document findings and actions taken during each inspection. Use logs for tracking.

Identify and Prioritize Potential Hazards

-

Catalog All Possible Risks: Start with a brainstorming session. Include staff from various roles. Think about slip hazards, fire risks, and equipment malfunctions.

-

Rank Risks: Use a risk matrix with categories like ‘High’, ‘Medium’, and ‘Low’. Focus on high-risk areas first.

-

Plan Mitigations: For high risks, develop action steps. For instance, replacing old equipment or adding safety signs.

Establish an Incident Response Plan

Having a good plan for when things go wrong is crucial. It ensures that accidents are handled quickly and efficiently.

Outline Steps for Reporting and Responding to Incidents

-

Create a Reporting Template: Use a simple form. Include fields for date, time, type of incident, and observation. Make it available online or in paper form.

-

Train Employees on Reporting Protocols: Conduct brief sessions on how to use the template. Emphasize urgency in reporting.

-

Set Up a Response Team: Assign roles like “Incident Commander” and “First Responder”. Make sure everyone knows their duties.

Include Emergency Contact Details and First Aid Procedures

-

Compile Contacts: List phone numbers of emergency contacts like management and local agencies. Display them clearly in the warehouse.

-

First Aid Training: Train several staffers in first aid. Refresh their training annually. Provide comprehensive first aid kits and keep them stocked.

Invest in Safety Technology

Using the right technology helps in the fire hazards, enforcing safety standards, and spotting issues early.

Software for Monitoring Safety Compliance

-

Choose a Safety Management App: Find software like EHS applications to track these processes. Look for features that offer inspection checklists, incident reporting, and analytics tools.

-

Regular Software Training: Train the team to use the software. Show them how to input data and read reports.

-

Automate Alerts: Set up alerts for expired inspections or missed checks. Ensure they go to managers and safety officers.

Install Cameras and Sensors

-

Survey Key Areas: Look at high-traffic zones, loading docks, and storage spaces. Decide where cameras are most needed.

-

Choose Smart Sensors: Pick sensors to detect temperature spikes, gas leaks, or unauthorized access.

-

Maintain Equipment: Perform regular checks on cameras and sensors. Ensure they are functioning properly.

By following these strategies, you can minimize risks and keep protect workers in your warehouse safe. Each step plays a vital role in maintaining an environment where accidents become less likely and response times are improved.

Warehouse Safety Compliance Updates 2024

-

New OSHA regulations require an annual review to stay compliant.

-

Annual safety training keeps staff updated on regulations.

-

The focus of the year is ergonomic hazard identification.

Stay Updated with OSHA Regulations

Review Changes

The past year brought several changes in warehouse safety rules. OSHA, a major regulatory body, released an inspection program aimed at warehouse safety hazards reducing risks at work. This program targets warehouses and last-mile delivery services, focusing on the protection of workers from common risks. It represents a major effort by OSHA and signals to companies the need to prioritize safe environments. Over the last twelve months, businesses have been urged to align their protocols with these new standards. Practically, this means businesses need to modify their safety guidelines to match OSHA’s latest directives.

Recent legislation, such as the Warehouse Worker Protection Act, further complements OSHA’s efforts. It introduces tougher safety measures and aims to improve training and reporting of warehouse hazards. This legislation stresses the importance of thorough training programs and stricter safety protocols. With such regulations in place, businesses should ensure their staff are aware of their rights and responsibilities. Enhanced safety features and comprehensive procedures for emergencies are now expected in warehouses. Keeping up with these regulations is not optional; it is a necessity.

Prepare for Future Changes

As we look ahead, these regulations show no sign of slowing or retreating. OSHA has made it clear that ongoing improvements depend on strict adherence to these rules. Going forward, the focus may expand further to include digital transformations in reporting and monitoring. Digital record-keeping fosters transparency and accountability within the industry. By 2024, it could become the norm, with more data-driven insights guiding safety practices. OSHA’s agenda reflects this trend, emphasizing the integration of tech to improve workplace health and safety. Companies should start considering how best to invest in digital solutions to streamline compliance. Waiting for mandatory compliance can result in penalties, so proactive adaptation is advised.

Conduct Annual Safety Training Refreshers

Schedule and Execute Training

Over the past year, mandatory safety training became even more critical for warehouse operators. Regular training sessions ensure all employees remain knowledgeable about new safety standards. The OSHA regulations mandate such sessions to cover not just machinery use but comprehensive emergency response plans. With the injury rate in warehousing being significantly high, consistent training can mean the difference between minor accidents and more severe injuries. Training sessions are not merely a formality; they are a vital part of risk reduction.

The importance of updated training is emphasized by the focused initiatives on ergonomic hazards. Workers need to understand the significance of ergonomic occupational safety and to prevent long-term injuries. Frequent refreshers help underline these stresses by targeting new risks and reviewing past ones. Companies that invest in these programs see a decrease in workplace injuries and illnesses. For 2024, as risk management strategies further develop, expect more tailored training sessions to address specific organizational needs.

Emphasize Compliance

Training sessions serve an additional purpose beyond knowledge sharing; they reinforce compliance. When conducted properly, they align staff behavior with regulatory standards. Keeping these sessions engaging ensures that employees are not only informed of safety risks but also fully understand their application. This year, the role of management in conducting and participating in these sessions becomes key. It emphasizes shared responsibility in maintaining a safe working environment. The last year has shown that when everyone in the organization understands and respects safety protocols, the work environment is notably safer.

As we look to the coming year, what comes next is increased regulation scrutiny. OSHA will likely further refine existing protocols to address the always-present worker safety gap. Enhanced employee training models and compliance checks are expected to play an active part in shaping warehouse safety. Businesses should aim to develop advanced safety modules that preempt these changes, ensuring they are not caught off guard. By taking proactive steps now, businesses can position themselves as leaders in warehouse safety, setting industry standards rather than merely trying to meet them. To enhance the safety culture even further, it’s beneficial for businesses to familiarize themselves with some important tips regarding warehouse safety. Staying informed about best practices allows management and staff to work together to create a safer working environment that consistently meets compliance and efficiency goals.

Effective Warehouse Safety Training Programs

-

Train staff for specific roles.

-

Encourage open safety discussions.

-

Enhance teamwork to improve safety.

Training is crucial for maintaining a safety culture and compliance. With thorough programs, employees act safely and efficiently. Let’s break down these training essentials.

Develop Comprehensive Training Modules

Tailor Modules to Specific Roles

Each employee in a warehouse has unique responsibilities. Craft training modules that cater to these specific roles. For instance, forklift operators need comprehensive sessions focusing on vehicle safety. Given that forklift accidents are the leading cause of death in warehouses, accounting for about one-third of all fatalities, specialized training can significantly reduce risks.

Address key tasks trip hazards and potential hazards for each position. This approach ensures workers are prepared for their specific duties. Regularly update these modules to include the latest safety procedures and equipment use guidelines.

Include Practical Exercises and Assessments

Theoretical knowledge is essential, but practical exercises bridge the gap between learning and real-world application. Design training to include hands-on activities. These exercises let employees practice their skills in a controlled, supervised environment. Simulated emergency drills can be particularly effective in preparing staff for unexpected situations.

Assess employee performance through tests and evaluations after modules or exercises. You can use these to gauge understanding and identify areas needing improvement. Continuous assessment helps ensure that training isn’t just a one-off event but an ongoing process, of nurturing a skilled workforce.

Foster a Safety-First Culture

Encourage Reporting of Unsafe Conditions

Empower employees to report unsafe conditions they observe without fear of reprimand. Create a clear reporting system – whether a digital platform or a simple paper form. You should explain the process during training sessions. Assure workers their reports are valued and taken seriously. This open line of communication can help identify and fix hazards quickly.

Work environments encouraging feedback typically experience lower accident rates. When employees feel their voices are heard, they are more likely to engage in proactive safety behaviors.

Promote Teamwork and Communication Among Staff

Safety is a team effort. All employees should understand their part in maintaining a safe workspace. Part of the training should emphasize collaboration. It is better to use group activities to strengthen teamwork. You should encourage team members to look out for each other. Promote clear communication across all levels of staff – from entry-level workers to management.

Facilitate regular safety meetings where staff can share safety tips and incident reports. By fostering a community feel within the warehouse environment, employees are more inclined to support one another and uphold safety protocols.

By developing comprehensive training modules and fostering a culture of safety, warehouses can be more secure and efficient. Regular safety training tailored to specific needs and roles highlights how ongoing education sustains an alert, capable, and prepared workforce.

Conclusion

As we wrap up our journey through warehouse safety, remember: these 15 top warehouse safety tips outlined here aren’t just guidelines—they’re lifelines for your business and workers. By implementing SOPs, maintaining cleanliness, and prioritizing PPE, you’re not just ticking boxes; you’re building a fortress of safety. Regular risk assessments and incident response plans are your radar, detecting threats before they materialize. Staying updated with OSHA regulations and fostering a safety-first culture transforms your warehouse into a beacon of best practices.

But the real power lies in your hands. Will you let these insights gather dust, or will you turn them into action? Imagine walking into your warehouse six months from now, and seeing a team that moves with confidence, operates with precision, and returns home safely every day. That’s not just a dream—it’s your new reality. As you consider your warehouse’s future, don’t overlook the importance of investing in the right tools. Equip your facility with essential safety gear and machinery that adapt to the evolving landscape of warehouse operations. Understanding the upcoming trends in warehouse safety equipment for 2025 can empower you to make informed decisions that enhance both safety and efficiency.

Your next step? Close this tab and implement one fire safety measure in the next hour. The clock starts now. Your warehouse’s future is calling. Will you answer?