In 2024, a warehouse isn’t just a storage space; it’s a bustling ecosystem where one wrong move can spell disaster. Every day, workers navigate potential hazards that most people never see. The clang of metal, the whir of forklifts, and the constant flow of goods – it’s a symphony of productivity and risk.

Think you’ve got safety covered? Think again.

Last year, over 200,000 warehouse workers suffered injuries on the job. That’s not just a statistic. It’s 200,000 lives disrupted, families worried sick, and businesses facing crippling costs. Implementing essential warehouse safety equipment is not just smart—it’s a must for every facility aiming to protect its people and assets.

But here’s the kicker: Most of these accidents were preventable.

The right safety equipment isn’t just a checkbox on a compliance form. It’s the invisible shield that stands between your team and disaster. It’s the difference between a close call and a tragedy.

Are you willing to gamble with those odds?

In this guide, we’re going to reveal the 10 essential pieces of warehouse safety equipment for 2024. This isn’t your grandfather’s safety checklist. We’re talking cutting-edge tech, innovative designs, hazardous materials, and gear so effective it feels like it’s from the future. Adopt these contemporary warehouse safety measures to foster a protected and regulatory-compliant storage facility.

But fair warning: Once you see what’s possible, you’ll never look at warehouse safety the same way again. You might even get angry at how much unnecessary risk you’ve been taking.

Ready to transform your warehouse from a potential deathtrap into a fortress of safety? Let’s dive in. Your team’s lives may depend on it.

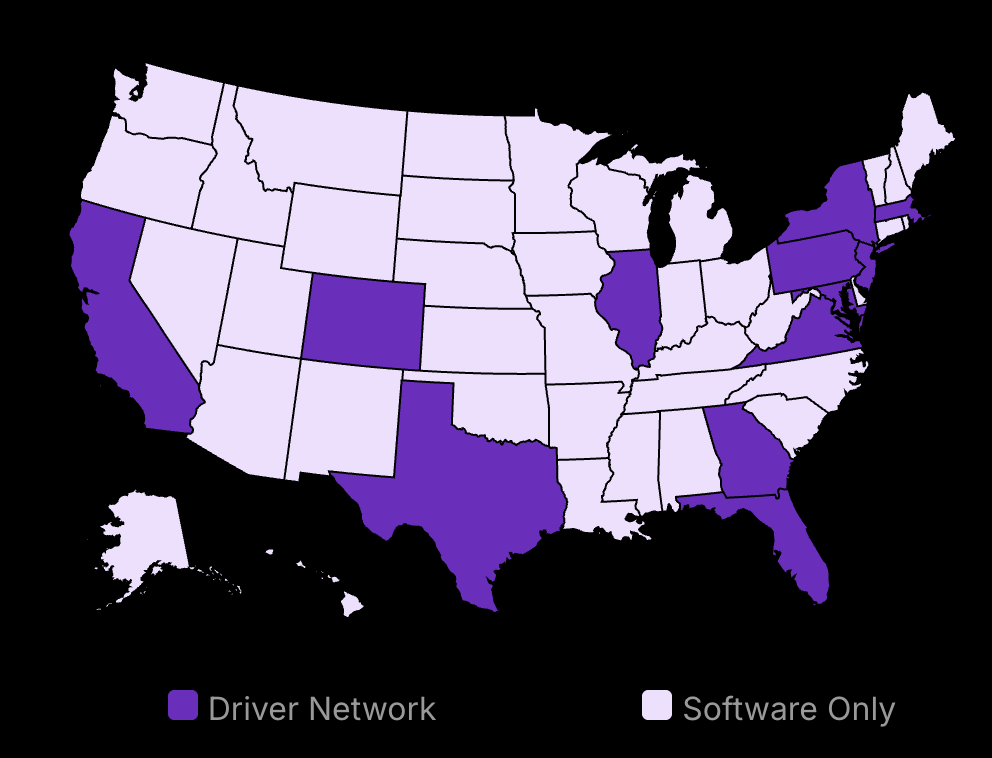

Lower your delivery costs by 23%

How we reduce costs:

- No delivery vehicle expenses

- Optimized local routes

- Pay-per-delivery model

- Average 23% delivery cost reduction

Top 10 Must-Have Warehouse Safety Equipment for 2024

Focus on key safety gear for warehouse operations.

Health and safety improvements through modern equipment.

Compliance with current industry safety standards.

Warehouse Personal Protective Equipment (PPE)

Types of PPE: Helmets, Gloves, and Footwear

Personal Protective Equipment (PPE) is the backbone of warehouse safety. Helmets, gloves, and footwear are essential elements. Helmets protect workers from head injuries caused by falling objects. Gloves guard hands against cuts, burns, and chemical exposure. Proper footwear reduces the risk of slips, trips, and falls, especially in wet or oily conditions. Maintain a secure warehouse environment by adhering to safety protocols and regularly updating your team on best practices for warehouse safety.

Different tasks may require specific PPE. Workers dealing with chemicals might need gloves that resist chemical reactions. For areas with heavy machinery, steel-toed boots are often necessary. Understanding these nuances ensures the right full protection equipment is in place. Implementing critical warehouse safety advice can significantly uplift the safety standards, safeguarding your workforce and minimizing hazards.

Importance of PPE for Preventing Injuries

Using PPE significantly reduces workplace injuries. A study by the U.S. Bureau of Labor Statistics found that head injuries dramatically decrease when helmets are worn. The same goes for hand and foot injuries when appropriate gloves and footwear are used.

Key Standards to Meet OSHA Requirements

OSHA(Occupational Safety and Health Administration) sets the standards for workplace safety, including PPE. Compliance with these standards is not optional—it’s mandatory. Helmets should meet ANSI/ISEA Z89.1 standards, gloves should comply with ANSI/ISEA 105, and footwear should align with ASTM F2413.

Non-compliance can lead to penalties and increased injury risks. Regular audits ensure that equipment remains up-to-date with the latest OSHA requirements.

High-Visibility Clothing

Benefits of Using High-Visibility Garments

High-visibility clothing is crucial for worker safety in environments with moving vehicles and equipment. These garments, often fluorescent with reflective strips, dramatically improve worker visibility, reducing accident risks.

For instance, in a warehouse where forklifts operate, high-visibility vests can decrease the chance of accidents by making sure forklift operators spot pedestrians quickly. This simple measure has proven effective in countless facilities worldwide.

How It Reduces Accidents in Busy Environments

Busy warehouse environments are fertile grounds for accidents. High-visibility clothing plays a crucial role here. A warehouse in New Jersey reported a 20% decline in near-miss incidents after implementing mandatory high-visibility clothing for all employees.

The clothing’s reflective properties ensure that low-light conditions do not compromise safety. Making this a standard can reduce costs and also enhance the perception of safety culture within the workforce.

Compliance with Safety Regulations

Several regulatory bodies mandate high-visibility clothing in specific industries. Compliance with standards like ISO 20471 ensures that the clothing meets the necessary visibility criteria. Non-compliance could result in fines or even operational shutdowns.

Fire Safety Tools: Extinguishers and Alarms

Different Types of Fire Extinguishers and Their Uses

Fire extinguishers are a basic yet vital component of warehouse safety equipment. They are categorized based on the fire types they combat. For example, Class A extinguishers handle fires involving ordinary combustibles, whereas Class B is for flammable liquids. Electric fires require Class C extinguishers, and so on.

The key is ensuring that the right extinguisher type is available and accessible throughout the facility and warehouse. Training staff on using these extinguishers is also a necessary step in fire preparedness plans.

Role of Fire Alarms in Early Detection and Safety

Fire alarms are critical for early detection. Advanced fire alarm systems not only alert personnel but also integrate with sprinklers and emergency lighting. A well-maintained alarm system can significantly reduce fire-related damages.

For instance, a study in Florida showed warehouses with interconnected fire alarm systems had lower fire-related downtime than those without. Early alerts give workers the crucial seconds needed to evacuate effectively.

Regular Checks and Maintenance Guidelines

Regular checks and maintenance of fire safety equipment cannot be overlooked. Fire extinguishers require monthly inspections and annual maintenance. Alarms need testing to ensure functionality.

Ignoring maintenance could lead to equipment failure at critical times. Developing a maintenance checklist and assigning responsible personnel ensures system reliability.

Elevating Warehouse Safety for a Secure Future

Safety in warehouses isn’t just about rules—it’s about people. The equipment we’ve explored forms the backbone of a safer work environment. Each piece adding safety equipment plays a crucial role, from basic PPE to cutting-edge automated systems. But remember, the best safety tool is awareness.

As we approach 2024, the focus on warehouse safety products will shift to sustainable, smart solutions that protect workers and the planet. The future of warehouse safety lies in customized training, real-time monitoring, and adaptive strategies.

Your next steps? Review your current safety setup. Identify gaps. It is better to invest in quality equipment. But most importantly, you should foster a culture-safe work environment where safety is everyone’s responsibility.

A safe warehouse is a productive warehouse. It’s where injuries decrease, morale soars, and efficiency peaks. By prioritizing safety, you’re not just protecting your workers—you’re securing your business’s future.