Are you struggling with chaotic inventory and high storage costs?

Just-in-time delivery for business owners can revolutionize your supply chain.

By syncing orders with production schedules, you’ll minimize waste and maximize efficiency.

Consider that Toyota uses this strategy to save billions – what could it do for your business?

In this guide for 2024, we break down the steps to implement this game-changer. Time to boost your bottom line without the headaches.

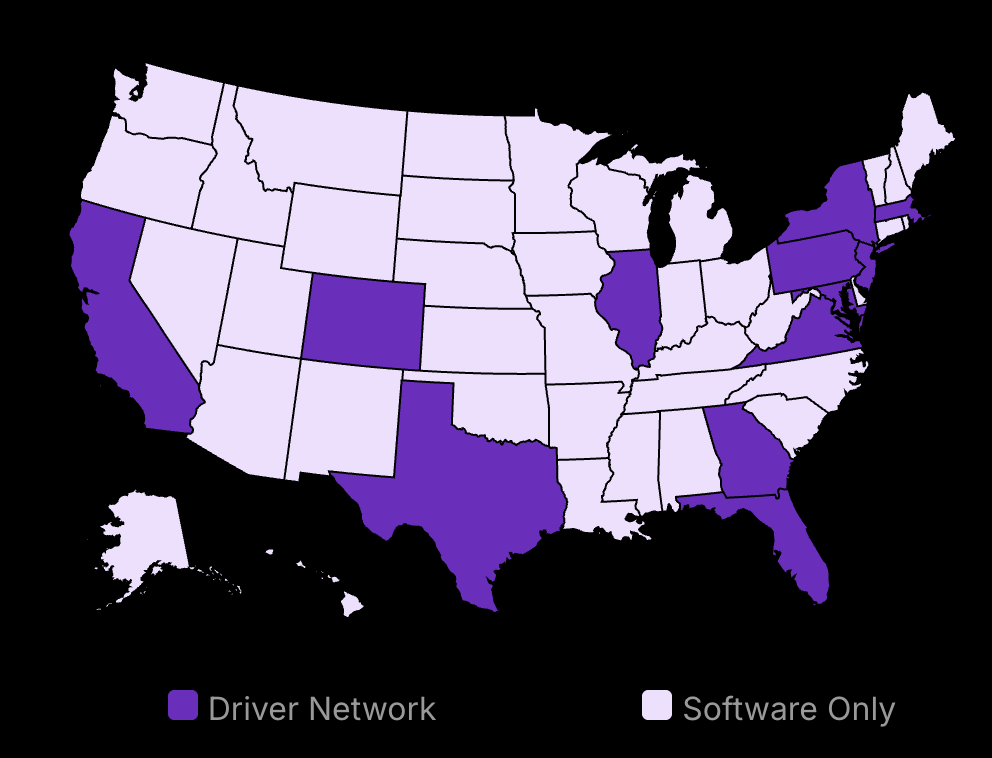

Metrobi drivers are rated 4.97 out of 5

Trusted by local businesses for:

- Background-checked professionals

- Specialized in business deliveries

- Same drivers for consistency

- 4.97/5 average delivery rating

What is Just in Time Delivery?

Definition and History

Just in Time delivery (JIT) is a methodology aimed at reducing inventory costs by receiving goods only as they are needed in the production process. Toyota pioneered it in the 1970s as part of its lean manufacturing policy. The concept gained global popularity, influencing numerous industries beyond automotive manufacturing. a JIT inventory system ensures that inventory levels are kept to a minimum, thereby reducing storage costs and waste.

Toyota’s implementation of JIT was pivotal. By only producing what was immediately needed, the company slashed its production costs and increased efficiency. This model proved highly successful, leading other firms to adopt the same JIT inventory management methodology, particularly in the manufacturing, retail, and logistics industries. The historical significance of JIT lies in its transformative impact on supply chain management, promoting operational efficiency and cost reduction. Understand how Toyota’s JIT implementation has influenced the components and efficiency of outbound logistics systems across various sectors.

Key Components of Just In Time Delivery

Accurate demand forecasting is critical for successful JIT implementation. Businesses need to predict customer demand precisely to avoid overproduction or stockouts. This involves collecting and analyzing historical sales data, market trends, and customer behaviors. Inaccurate forecasts can result in either surplus inventory—which negates the benefits of JIT—or insufficient stock, leading to missed sales opportunities. Understanding customer demand patterns through effective forecasting techniques is essential for optimizing JIT inventory levels and reducing waste.

Strong relationships with reliable suppliers are crucial. Trust and open communication ensure that suppliers can deliver the right amount of goods at the right time. Companies often enter into long-term contracts with suppliers to secure timely deliveries. This strategy helps mitigate risks associated with supply chain disruptions and enables smoother operation of the JIT system. Learn how the management of outbound logistics can further streamline operations by ensuring timely delivery of products to customers.

Logistics and transportation need to be highly efficient to meet the tight schedules dictated by JIT. This means having reliable transport partners and possibly even investing in real-time tracking technologies. Efficient transportation systems help ensure that materials and products are quickly moved from suppliers to production lines or retail outlets, minimizing delays and maintaining the flow of goods. Understand the importance of logistics beyond the warehouse: Explore how optimizing outgoing logistics processes enhances distribution effectiveness and ensures on-time product delivery.

Just In Time Delivery vs. Traditional Inventory Management

Traditional, inventory management strategy involves holding large stocks of goods to mitigate the risks of supply chain disruptions. While this approach can prevent stockouts, it ties up capital in inventory and incurs significant storage costs. JIT, on the other hand, aims to streamline these processes by minimizing inventory levels and reducing waste. Explore how utilizing dock swapping techniques boosts efficiency by directly moving products from inbound to outbound vehicles, bypassing the need for storage and further streamlining inventory management.

Benefits of JIT

The key benefits of JIT include lower inventory holding costs, reduced waste, and increased efficiency. Companies implementing JIT can free up capital that would otherwise be locked in inventory. This lean approach often results in higher profitability and improved cash flows. Additionally, JIT can lead to better product quality as issues are identified and resolved more promptly. Unlock the potential of JIT production methods and understand how they can transform your approach to manufacturing, focusing on the fundamental strategies.

Drawbacks of Traditional Inventory

Traditional inventory management carries several disadvantages. High inventory levels can lead to increased storage costs and reduced liquidity. Goods held in inventory for prolonged periods run the risk of obsolescence, especially in fast-paced industries like technology and fashion. Furthermore, large inventories can hide production inefficiencies and issues, delaying process improvements. Understanding the benefits of advancing scheduling over traditional inventory methods can significantly lower storage costs and reduce the risk of obsolescence.

How to Implement Just in Time Delivery in Your Business

Step 1: Assess Your Current Supply Chain

Before adopting Just in Time delivery (JIT), it’s pivotal to evaluate your existing supply chain. This involves scrutinizing each stage of the process – from procurement to warehousing to point-of-sale. Identify inefficiencies and areas where time and resources are wasted.

Mapping the Entire Flow

Begin by mapping the entire flow of goods and materials. This visual representation helps in pinpointing bottlenecks and redundant steps. Use supply chain management software to track the movement of inventory. Enhance your logistics efficiency by understanding how to calculate the capacity for carrying loads, ensuring optimal use of your transportation resources.

Key Metrics to Analyze

Focus on key metrics like lead times, inventory turnover, and supplier reliability. Understanding these metrics provides a benchmark against which improvements can be measured.

Step 2: Choose the Right Suppliers

The effectiveness of just in time delivery largely hinges on the reliability of your suppliers. Selecting the right partners is therefore critical. Look for suppliers who have a proven track record and can deliver high-quality materials on demand. Learn how to manage situations when goods are on backorder to maintain a steady supply chain and ensure customer satisfaction.

Evaluating Supplier Performance

Select suppliers by evaluating their performance on criteria such as lead time, flexibility, and accuracy. Regular audits can ensure that they meet your standards. Develop a scorecard to quantify supplier performance.

Building Strong Relationships

Foster long-term relationships with your suppliers. Regular communication and collaboration can help in synchronizing supply schedules, improving reliability, and reducing delays.

Step 3: Invest in Technology

To seamlessly implement JIT, investment in technology is non-negotiable. Technology automates processes, offering real-time data and insights that are crucial for decision-making. Enhance your CSA ratings and enhance operational efficiency with cutting-edge tech strategies, ensuring you’re always ahead in compliance and performance.

Inventory Management Systems

Implement advanced inventory management systems (IMS) that provide real-time tracking. An IMS can forecast demand accurately, helping you maintain optimal inventory levels.

Supply Chain Analytics

Use supply chain analytics to gain deeper insights into your operations. Analytics can predict potential delays and suggest corrective actions.

Step 4: Train Your Team

A well-trained team is critical for the success of JIT delivery. Equip your employees with the necessary skills and knowledge to implement and manage JIT processes.

Comprehensive Training Programs

Design comprehensive training programs that cover the principles of JIT, the technology used, and best practices. Ensure training is hands-on and offers practical insights rather than just theoretical knowledge.

Encouraging Continuous Learning

Promote a culture of continuous learning. Encourage employees to stay updated with the latest trends and innovations in supply chain management. This can be facilitated through workshops, seminars, and online courses.

Step 5: Monitor and Adjust

The final step involves continuous monitoring and adjustment of JIT processes. Constant vigilance ensures that any issues are quickly identified and rectified, maintaining the efficiency of your supply chain.

Using Key Performance Indicators (KPIs)

Develop a robust system of KPIs to monitor performance. Metrics such as order accuracy, lead time, and inventory levels should be tracked regularly.

Regular Reviews and Adjustments

Conduct regular reviews to assess the effectiveness of JIT practices. Be prepared to make adjustments based on these assessments. This iterative process helps in refining operations and sustaining improvements over the long term.

Benefits of Just in Time Delivery for Business Owners

Cost Savings

Reducing warehousing costs is a leading benefit of just in time delivery. When businesses receive goods only as they are needed, they don’t have to maintain large inventories. This means less money spent on storage space, less capital tied up in inventory, and fewer resources allocated to managing stock. Imagine the financial impact of reducing your storage needs by 50%. This is not merely theoretical—many businesses achieve such savings by implementing JIT systems.

Additionally, material waste is sharply reduced under JIT. Overproduction minimal inventory is minimized, and items that might become obsolete or damaged while in storage are no longer an issue. This savings translates directly to the bottom line, allowing businesses to allocate funds more strategically. For example, money saved through JIT can be redirected towards innovation, marketing, or employee development.

Improved Efficiency

Streamlined operations are another core advantage of adopting JIT delivery. When inventory levels are optimized, workflows become more predictable. This allows managers to plan production schedules with greater accuracy. Efficient use of resources means less downtime between production runs, which boosts overall productivity. Workers aren’t left waiting for materials, and machines run at optimal capacity.

Communication and coordination also reach new heights under a JIT system. Suppliers need to be tightly integrated into the operational rhythm of the business. This creates stronger relationships and more reliable supply chains. Dependability becomes the norm, not the exception. Over time, businesses and suppliers develop mutual trust, fostering collaboration that drives even greater efficiencies.

Better Customer Satisfaction

With JIT systems, businesses can better match supply with customer demand. This reduces lead times and ensures that customers receive their orders faster and with fewer errors. Faster delivery times can lead to significantly higher customer satisfaction levels.

Moreover, quality control is inherently improved in a JIT environment. Since products are made in smaller quantities and closer to the time of order, there is less room for defects to be mass-produced. Stringent quality checks can be implemented more easily, ensuring that what reaches the customer is of higher quality.

Lastly, customizable solutions become more feasible. With less inventory clogging up storage, businesses can be more flexible and responsive to customer needs. They can offer more tailored products or quicker modifications, on an as-needed basis thus further enhancing customer satisfaction and opening new revenue streams.

Business owners can see a transformative change in how their operations run by focusing on these key benefits—cost savings, improved efficiency, and better customer satisfaction. This not only enhances the bottom line but also builds a competitive edge that’s hard to match.

Challenges and Solutions in Just in Time Delivery

Supply Chain Disruptions

Supply chain disruptions can derail even the best-laid JIT plans. Natural disasters, geopolitical tensions, and global pandemics, like COVID-19, expose vulnerabilities. These disruptions can severely delay shipments and halt operations. Explore how enhanced outbound logistics systems can mitigate the impact of supply chain disruptions and maintain steady operations.

Overcoming Unpredictability

One solution is diversifying suppliers. Relying on multiple sources reduces the risk if one shuts down. Another approach is with supply chain companies using technology for real-time monitoring. Tools like IoT sensors and blockchain ensure transparency and quicker responses to issues.

Building Resilience

Investing in local suppliers can also help. While it might be costlier upfront, it provides a buffer against global disruptions. Finally, maintaining a small buffer stock of critical items ensures some leeway during unforeseen disruptions.

Dependence on Suppliers

Excessive reliance on suppliers makes businesses vulnerable to their inefficiencies. Delays or quality issues from a single supplier can cripple the production line. A single point of failure in the supply chain can have cascading effects.

Mitigating Supplier Risks

Establishing strong relationships with suppliers is crucial. Regular communication and audits ensure they maintain high standards. Contractual agreements that penalize non-compliance can also enforce accountability. Encouraging suppliers to adopt similar JIT principles ensures they align with your operational goals.

Collaborating for Success

Another strategy is collaborating closely with suppliers on improvements. Sharing data and forecasts helps them plan better and meet your demands efficiently. Some companies even provide financial and technical assistance to their suppliers to enhance their capabilities.

Implementation and Inventory Costs

Adopting JIT isn’t cheap. Initial setup requires significant investment in technology, hiring experts, and training staff. However, these costs often deter businesses without a long-term outlook.

Balancing Costs and Benefits

Cost-benefit analysis is critical. While the upfront costs are daunting, the long-term efficiency gains and reduced waste can offset them. Tailoring JIT to specific areas of your business can also minimize initial expenditure while showcasing its benefits.

Funding and Financial Strategies

Securing funding for JIT implementation can be challenging. Exploring various financing options such as government grants, loans, or private investors can be beneficial. A phased implementation approach allows your business to spread out costs and see incremental improvements.

Take some time to reflect on the challenges detailed here and how they might affect your business operations. The next section will provide you with foundational knowledge on Just in Time Delivery methodologies to better understand these challenges.

Future Trends in Just in Time Delivery

Integration with AI and Machine Learning

The integration of AI and Machine Learning into just in time delivery is revolutionizing how businesses operate. These technologies enhance predictive analytics, allowing companies to forecast demand with heightened accuracy. This minimizes overproduction and reduces inventory costs, ensuring that resources are used efficiently.

AI algorithms can analyze vast amounts of data from various sources, such as historical sales data, market trends, and even social media activity. These insights allow businesses to predict demand spikes or lulls more accurately. For example, AI can identify patterns that human analysts might miss, offering a more nuanced and precise forecast.

Machine Learning takes it a step further by continuously learning and adapting to new data. It can autonomously adjust inventory levels based on real-time sales data and predictive analytics, ensuring that stock levels are always optimal. This adaptive learning process makes the supply chain more resilient and responsive to market fluctuations.

Sustainability and JIT

Sustainable business practices are no longer optional; they are a critical component of modern just in time delivery systems. As consumer and regulatory pressures for greener operations grow, businesses must adapt their implement JIT delivery practices to be more environmentally friendly. Explore how eco-friendly transport solutions can elevate your profitability and align with your commitment to sustainable operations.

Reducing Waste and Carbon Footprint

Just in time delivery inherently reduces waste by aligning production closely with demand, thereby the inventory system minimizing excess inventory. However, integrating sustainability into JIT goes beyond this. For example, companies can use eco-friendly packaging, optimize transport routes to reduce emissions, and ensure that supply chain partners adhere to sustainable practices. Additionally, adopting green cold chain logistics practices can enhance sustainability further by ensuring temperature-sensitive goods are transported efficiently and eco-consciously.

The Role of Circular Economy

Incorporating a circular economy approach can further enhance sustainability. This means designing products with their end-of-life in mind, facilitating recycling or re-use, and thus reducing the overall environmental impact. By creating a closed-loop system, businesses can ensure that their just in time delivery processes are as sustainable as possible.

Globalization and JIT

Globalization has significantly impacted just in time delivery systems. It has expanded supply chains across borders, increasing both opportunities and challenges.

Supply Chain Complexity

With globalization, supply chain management companies and chains have become more complex and interconnected. This complexity requires robust JIT systems to handle the extended networks. Technologies like blockchain can enhance transparency and traceability across global supply chains, ensuring that every step is monitored and optimized.

Risks and Opportunities in a Global Market

While globalization offers access to a broader market, it also introduces risks such as political instability, trade wars, and logistical challenges. Businesses must develop risk management strategies to mitigate these risks. Diversifying suppliers and maintaining buffer stocks can help in dealing with unforeseen disruptions without sacrificing the benefits of JIT.

By levering the advancements in AI and Machine Learning, ensuring sustainability, and navigating the challenges and opportunities of globalization, businesses can optimize their JIT delivery systems for the future. These trends will shape the landscape of the JIT delivery services, making it more efficient, sustainable, and globally integrated than ever before.

Your Path Forward with Just in Time Delivery Production Process

Implementing Just in Time delivery can trim your inventory costs, boost operational efficiency, and elevate customer satisfaction. Remember, mastering JIT requires precise planning, dependable partnerships, and continual monitoring.

Nailing down just in time delivery brings exponential benefits to your bottom line. Start by assessing your current supply chain capabilities. Can your suppliers meet this demand for precision? If not, now’s the time to identify reliable partners who can.

Have you thought about how JIT could transform your operations in 2024? Evaluate, implement, and see the difference.