In 2024, a manufacturing company lost $2.3 million due to poorly managed purchase orders. Their story isn’t rare. Every day, small businesses and larger companies waste time and money on purchase order mistakes that are simple to fix.

Look at your own business. How much time did your team spend last week searching for missing purchase orders, tracking purchase orders, or chasing approvals? Or fixing errors that could have been prevented by using a more efficient PO system? It’s not just about sending purchase orders—it’s about the process of making your business operations easier.

Let’s be clear: Purchase orders aren’t just paperwork. They’re the backbone of your business operations, whether it’s for recurring purchases or one-time purchases. When they work well, your business flows. When they don’t, everything slows down, from the incoming orders to the shipping information. A standard purchase order, for example, can prevent duplicate orders and reduce mistakes that could affect your total cost.

Importance of PO Management: Disrupted supply chains can lead to a financial loss of up to 62%, emphasizing the importance of efficient purchase order management

The solution isn’t complex. You don’t need expensive software or a complete system overhaul. What you need is a straightforward approach that works—one that supports your long-term agreements with sellers and helps you manage the delivery schedule for large quantities of goods or services.

This guide shows you five proven methods to make your purchase orders work better. These aren’t theoretical concepts—they’re practical steps that real businesses use every day. You’ll learn how to:

Cut approval times by streamlining the approval process for each purchase order PO.

Reduce order errors, such as mismatched billing addresses or missing item numbers, that lead to problems for both the buyer and seller.

Save 12 hours per week on paperwork, including tracking the seller receives the goods or services.

The best part? You can start using these methods today. No special training is needed. No complex technology is required. Implementing a simple e-procurement solution will eliminate longer paper-based methods and improve your order process.

Are your purchase orders causing you headaches? By the end of this guide, you’ll have the tools to fix them. Let’s make your purchase order process simple, fast, and error-free, whether you’re handling planned purchase orders or dealing with specific dates for recurring purchases.

Boost customer satisfaction with just a few clicks

Most-Loved Features:

- On-demand drivers

- Real-time GPS tracking

- Delivery confirmation photos

- Over 50% of customers report a smoother delivery experience

Purchase Order Process Improvement: Step-by-Step Guide

Assess and refine the current purchase order steps to find and fix issues.

Use tools that automate the purchase process to save time and reduce errors.

Regular checks and updates ensure ongoing improvement.

Step 1: Assess Current Purchase Order Process

Understanding your process is key. Start by identifying current bottlenecks. Look for delays or points where the process often stalls. This might be in communication, approvals, or when waiting for information. A practical way to do this is to map out each step in the purchase order workflow. This could be via a flowchart. One effective way to enhance your purchase order management is by utilizing reliable purchase order software. These tools can simplify the process, giving small businesses the ability to manage approvals and track orders with ease. For more information on the best available options, check out our article on top tools for managing purchase orders in small businesses.

Next, list all key stakeholders involved. This includes anyone who requests, approves, or is affected by the purchase order. Understanding who’s involved helps streamline communication and decision-making. Engage with these stakeholders to gather insights about the current process and any pain points they face.

Step 2: Implement Automation Tools

Automation can significantly reduce manual errors and save time. Start by researching software solutions. Look for tools that fit your company’s size and needs. The software should integrate with existing systems like your ERP or inventory management.

Reduction in Processing Time: One case study shows a company achieving a 75% reduction in the time taken to process purchase orders after implementing automation.

Once you choose the right tool, focus on training. Make sure employees understand how to use the new system. Create user guides or host demo sessions to ensure a smooth transition. Regular training updates can keep your team efficient as new features roll out.

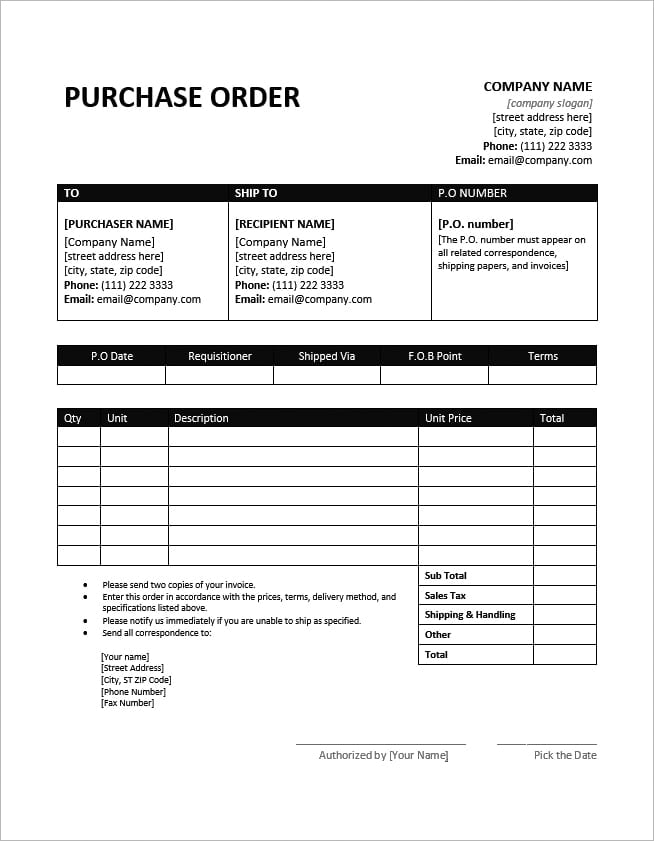

Step 3: Standardize Purchase Order Templates

Consistency is key. Develop unified templates for your organization. Templates should include essential fields like the requester’s name, item details, and quantities. Standard templates help maintain clarity across departments and reduce errors.

Ensure consistency by maintaining a single version of each template. Regularly update these, incorporating feedback from users to improve usability. Clear and consistent documentation can simplify both the order process and record-keeping.

Step 4: Incorporate Approval Workflows

Clear approval workflows reduce delays. Define who approves what and in which order. This hierarchy can vary by purchase size or department needs. A simple chart can clarify the hierarchy for all involved.

Leverage automation to track approvals. Automated reminders prompt approvers, reducing waiting time. Set follow-ups to ensure orders move through the process efficiently. Automation helps maintain transparency and accountability.

Step 5: Monitor and Review Regularly

Regular oversight is crucial for continuous improvement. Schedule audits to review the purchase order steps and their effectiveness. Audits can highlight discrepancies, unnecessary steps, or areas for improvement.

Reduction in Cycle Times: Implementations of purchase order automation can reduce cycle times by up to 60%, significantly enhancing operational efficiency.

Collect feedback from stakeholders regularly to refine your process. Surveys or meetings can provide valuable insights into both strengths and areas for improvement. Make revisions based on this feedback to keep the system efficient and responsive to the organization’s needs.

Efficient Purchase Order Management Techniques

Track orders in real-time.

Build strong supplier relationships.

Save money and time.

Utilize Real-Time Tracking

Step 1: Choose a Reliable Tracking System

Research different tracking systems that fit your business needs. Look for features like real-time updates, user-friendly interface, and integration capabilities with your existing systems. Use free trials if available to see which one works best.

Step 2: Implement the Tracking System

Once you choose a system, roll it out in phases. Start with one department to troubleshoot initial issues. Provide training sessions for staff. Ensure everyone knows how to access real-time updates, adjust settings, and report issues.

Step 3: Set Up Real-Time Alerts

Configure the system to send notifications whenever there are changes in the order status. Alerts should target relevant team members. This means defining clear roles for those who need these updates.

Step 4: Monitor Tracking Performance

Consistently review system performance. Encourage feedback from staff on ease of use and effectiveness. If delays occur despite real-time tracking, identify the cause and rectify it promptly. Tracking should not just alert but also assist in proactive decision-making.

Reporting and Analytics

Step 5: Analyze Tracking Data

Regularly review analytics provided by your tracking system. Look for patterns such as frequently delayed orders or consistent supplier issues. Use these insights to make informed decisions and improve purchase order efficiency.

Step 6: Share Insights with Team

Communicate key findings in regular meetings. Keep everyone updated on performance metrics and action points for improvement. Establish clear communication channels for team members to report issues and share suggestions.

Leverage Supplier Relationships

Step 1: Build Strong Supplier Partnerships

Focus on creating long-lasting relationships. Consider suppliers as a part of your team. Engage them in strategic conversations. Understand their capabilities and limitations. Treat suppliers with the respect given to co-workers. This sets the foundation for good collaboration.

Step 2: Negotiate Better Terms

Work with your suppliers to renegotiate terms that benefit both parties. This may involve bulk discounts or extended payment terms. Focus on win-win scenarios. Effective negotiation should be an ongoing process as market conditions change.

Step 3: Evaluate Supplier Performance

Use metrics like delivery time, product quality, and cost-effectiveness to assess suppliers. Schedule regular reviews to discuss performance and areas for improvement. Document these evaluations to build a comprehensive view of each supplier’s value.

Step 4: Collaborate for Innovative Solutions

Invite suppliers to problem-solving sessions. Their industry expertise could bring valuable insights. Their involvement in these discussions can foster better alignment on goals and expectations. Suppliers can help innovate production methods or develop new products that are cost-effective.

Setting Transparent Goals

Step 5: Define Clear Expectations

Set clear Key Performance Indicators (KPIs) with suppliers. Outline these in written agreements to avoid ambiguity. Regularly revisit and, if necessary, adjust these KPIs to stay in alignment with business objectives and external market pressures. This approach minimizes risks associated with handshake agreements, as suggested by Dave Blanchard.

Step 6: Foster Open Communication

Maintain transparency in all dealings. Use data from real-time tracking to keep both sides informed. Clarify expectations and get feedback from suppliers on how to improve processes. Efficient communication leads to better trust and improved operations.

Simplifying Procurement Procedures for Better Efficiency

Save time by choosing the right suppliers quickly.

Improve order accuracy with better forecasting.

Reduce expenses by aligning purchasing with inventory.

Streamline Supplier Selection

The first move in simplifying procurement is smart supplier selection. It sets the foundation for smooth processes.

Establish Criteria for Evaluating Suppliers

Define clear criteria. Focus on price, quality, delivery times, and reliability. These factors ensure the supplier can meet business needs.

Prioritize criteria based on what is most important. For example, if fast delivery is key, weigh it higher.

Create a scoring system. Rate each supplier based on these criteria. This helps compare suppliers easily.

Automate RFQ and Vendor Onboarding Processes

Use software solutions. Automate Request for Quotation (RFQ) processes. This reduces manual entry errors. Platforms like SAP Ariba or Oracle are popular options.

Simplify vendor onboarding. Automate data collection using forms that suppliers fill out. This ensures accuracy and saves time.

Keep documents digital. Store vendor contracts and details electronically for easy access.

Enhance Order Forecasting

Order forecasting is essential for procurement. It reduces the risks of over or under-stocking.

Use Historical Data for Predictions

Collect past order data. Review sales trends and seasonal fluctuations. This data helps predict future demand accurately.

Implement forecasting tools. Software like Microsoft Dynamics or NetSuite helps create demand forecasts.

Regularly update data. Reassess data monthly to refine predictions with the latest information.

Align Purchasing with Inventory Management

Integrate systems. Ensure purchasing and inventory management systems communicate seamlessly.

Set reorder points. Establish when items need reordering automatically. This reduces manual checks and stockouts.

Conduct inventory audits. Regular audits help verify stock levels and assess forecast accuracy.

By making the supplier selection and forecasting processes more efficient, businesses can simplify their procurement procedures. This leads to better efficiency and smoother operations.

Advanced Tips for Enhancing Business Workflow for Purchase Requisitions

Enhance communication and cut down on errors.

Shift to digital and streamline with existing tools.

Boost efficiency with clear channels and reduced paperwork.

Optimize Communication Channels

Effective communication is a game changer. Busy professionals need smooth and clear communication to handle purchase orders efficiently. Proper channels are key. Set up direct paths for communication within your team and with suppliers. This clarity helps prevent misunderstandings and ensures everyone is on the same page.

Identify the Right Tools: Start by selecting tools that fit your business needs. Tools like Slack or Microsoft Teams allow for quick and clear communication. Pick what’s best suited for your team’s workflow.

Set Up Dedicated Communication Channels: Create specific channels for different tasks. This could include a supplier communication channel for issues related to orders and a separate internal channel for team discussions.

Automated Reminders and Alerts: Use software to send automatic notifications. This helps keep track of deadlines and important dates. It also reduces the chances of missing critical follow-ups. This should be paired with a system that records these communications for future reference.

Regular Check-Ins: Set up routine check-ins with your team and suppliers. This ensures updates are consistent and any potential issues are quickly addressed. Schedule these at times convenient for all parties involved.

Visual Aids for Clarity: Use symbols or tags in communication tools to indicate priority tasks or issues. Doing so can provide at-a-glance clarity.

Reduce Paperwork and Go Digital in Your Purchasing Department

Moving away from paper not only saves trees but also boosts your workflow efficiency. Traditional methods can cause delays and errors. Digital solutions enhance accuracy and speed.

Switch to Digital Invoices: Using digital invoicing cuts down on errors. Align this with your accounting systems for simpler financial tracking.

Select the Right E-Invoicing Platform: Choose a platform with easy-to-use features. Ensure it supports various formats and integrates smoothly with your existing systems. This ensures a seamless transition from paper to digital.

Train Your Team: Equip your team with knowledge about the new system. Conduct workshops or training sessions to ensure everyone knows how to use the digital tools effectively. This cuts down on user errors and boosts confidence in handling new tech.

Archive and Secure Data: Implement cloud storage for secure archiving of digital invoices. This not only provides easy access but ensures that you comply with legal requirements regarding the storage and retrieval of invoices.

Monitor and Evaluate: Regularly review the effectiveness of going digital. Gather feedback from your team and suppliers to make improvements. Use analytics and assess productivity levels to measure the impact of the transition on efficiency.

Improved Tracking: A survey indicated that 75% of organizations reported improved ability to track spending and monitor budgets after implementing purchase order automation.

Integration with Existing Systems

Ensuring a smooth integration with current systems is vital. It brings together different processes under one roof:

Asses Compatibility with Existing Systems: Begin by evaluating your current systems. The goal is to identify potential integration challenges. Whether you have an ERP, CRM, or other databases, your new digital tools should seamlessly work with them.

Utilize APIs: APIs, or Application Programming Interfaces, enable different software applications to communicate with each other. Leverage these to integrate e-invoicing platforms and purchase order systems.

Perform a Pilot Test: Before fully committing, run a pilot test. Choose a small department or a specific process to trial the integration. Monitor for any glitches or issues. This step helps in ironing out potential problems early.

Gather Feedback and Iterate: After the pilot, obtain feedback to understand the pain points and areas for improvement. Make necessary adjustments before a full-scale rollout across the organization.

Data Backup Plans: Always have a backup plan. Ensure data is backed up regularly to avoid accidental data loss during the integration process.

By optimizing communication and reducing paperwork, you elevate the entire purchase order process. These steps pave the way for a more efficient, digital-ready business operation.

Troubleshooting Common Purchase Order Issues

Tackle purchase order delays and streamline processes.

Mitigate supplier miscommunication and set clear terms.

Enhance efficiency and supplier relationships.

Address Delays in Order Processing

Delays in order processing can disrupt your supply chain and lead to missed opportunities. Identifying the root causes is your first step. Utilize tools like the Process Monitor or Sourcing Workbench to analyze where delays often occur. These tools help you pinpoint inefficiencies by providing a clear overview of order movement within the system.

Once you’ve identified recurrent bottlenecks, implement changes that address these disruptions. Solutions can include automating specific approval processes or reallocating roles to improve efficiency. It’s vital to create a systematic approach that ensures each order progresses smoothly through each stage. Regularly review your process to stay updated on new issues.

Identify Root Causes of Delays

To identify root causes, focus on common areas: approval steps, supplier response times, and inventory issues. Approval delays occur if there’s a lack of clarity in the hierarchy. Setting automated notifications can remind team members of pending approvals. Delays from suppliers might need a renegotiation or setting clearer lead times from the start. If inventory issues cause delays, check if forecasting matches order trends. Cross-check your forecasts with past data to minimize these mismatches.

Resolve Miscommunications with Suppliers

Miscommunication with suppliers can lead to order errors or delays. Begin by establishing clear expectations and guidelines at the start of any partnership. Detailed contracts outlining terms, deadlines, and responsibilities can lessen confusion. Use simple language and SMART goals to keep agreements understandable and actionable.

Maintaining open communication is equally crucial. Regular check-ins via online meetings or chat platforms can ensure everyone is on the same page. Fostering a culture of openness, honesty, and respect, and sharing relevant information can build trust. By building a robust communication framework, you minimize misunderstandings and strengthen your relationship with suppliers.

Set Clear Expectations and Guidelines

To set clear expectations, start by defining key goals and aligning them with your business strategies. Share these guidelines in a structured format that vendors can easily reference. Setting up regular updates ensures both parties adapt to changes swiftly. Regular follow-ups help monitor compliance with these guidelines, facilitating continuous improvement in vendor relationships.

Further Resources and Reading

AI will change procurement significantly by 2025.

Supply chain tech spending may hit $19 billion yearly.

Sustainability is reshaping supply chain processes.

Related Topics on Procurement and Supply Chain

Advanced procurement and supply chain strategies have captured significant attention in recent years. As artificial intelligence investments continue their dramatic upward trajectory in procurement, organizations are increasingly embracing smarter, more automated processes. AI’s impact spans across industries, generating substantial economic value worldwide. Business sectors are actively incorporating these technological advances to enhance their operations and results. This transition to AI-driven solutions represents more than a temporary trend—it has become a crucial competitive advantage in today’s business landscape.

AI Spending Growth: According to a report from Focal Point, AI spending in procurement is expected to grow by 446% by 2025, significantly outpacing traditional SaaS tool growth.

Why Streamlining Purchase Orders Matters

Streamlining purchase orders isn’t just about cutting stress; it impacts efficiency and cost management. Businesses find that efficiencies in purchase orders translate to cost savings and improved operations. With AI’s expansion, the procurement process becomes more impactful. Aligning technology with strategy means more informed decisions, faster.

Cost Reduction: Companies that automate their purchase orders experience a 20% reduction in costs associated with supplier management.

Benefits of streamlined processes include:

Business Efficiency: Automating purchase orders cuts down manual errors and speeds up processes.

Cost Management: Efficient order processing reduces unnecessary expenses, bolstering the bottom line.

Future Developments: As digital supply chain technologies exceed $16.26 billion annually by 2025, keeping ahead in tech is vital. Companies unable to integrate these trends risk falling behind.

Debunking Common Myths in Procurement

Some believe that streamlining purchase orders is just about cost-cutting. This is false. Streamlining improves overall business agility—a non-financial metric that boosts competitiveness. Another myth is that automation replaces jobs. But, it lets employees focus on strategic roles, increasing job satisfaction and growth potential.

Faster Data Extraction: Automated systems can extract data from purchase orders in just 30-60 seconds, compared to hours or days required for manual processing.

Conclusion

Purchase orders are not just forms. They shape how your business runs, ensuring that each contract purchase order is clear and serves as a legally binding contract between your business and suppliers. The steps we covered help you build a strong foundation for growth and success in the purchasing process.

Think about what happens when you put these changes in place: faster approvals, fewer mistakes, and better relationships with suppliers. Small improvements add up to big wins for your business, especially when you track purchase orders and streamline the buying process.

Your next steps are clear. Pick one area to improve first – maybe it’s creating standard templates or setting up electronic purchase orders for easier management. Start small, test the changes, and build from there. Remember that good systems, like a blanket purchase order for repeat purchases, need time to work well.

Keep checking how your new process works. Talk to your team about what’s working and what needs to change, especially the delivery details and expected delivery date. The best purchase order systems grow and change as your business does, ensuring that each legally binding document is tracked effectively.

You now have the tools to make your purchase orders work better. These changes will save time, cut costs, and help your business run smoother, from purchasing goods to completing typical purchase order tasks. Get started today by picking one improvement to focus on. Your future self will thank you for taking this step toward better business operations.

This is your chance to turn a basic business task into a strategic advantage. The sooner you begin, the sooner you’ll see results by creating purchase orders that are both efficient and effective.